Recently, we received an order from our regular customer in Nigeria,which includes products such as carbon and stainless steel fittings, and flanges. One of the products is an API 6A flange made of ASTM A694 F60 material. API 6A flange is often used in the petroleum and natural gas industry and is resistant to high pressure and temperature, so the quality requirements for the flange are relatively strict. we (Shanghai Zhucheng Pipe Fitting Manufacturing Co., Ltd.) has been committed to the production and sales of pipes and fittings for more than ten years. We are very familiar with the production standards and requirements of API6A flanges. Therefore, we quickly won this order with professional product knowledge and competitive pricing.

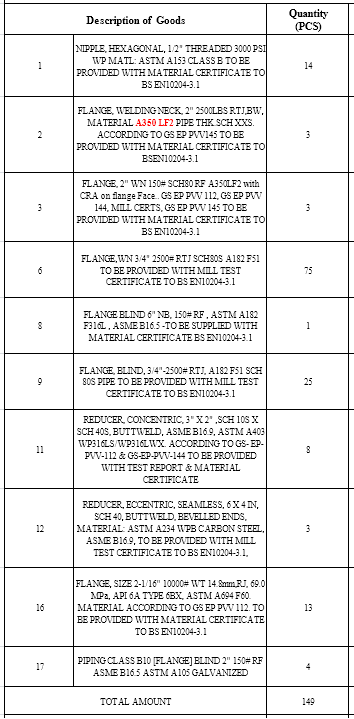

Purchase Order List

What Is API 6A Flange

API 6A flange is a flange manufactured according to the production standards established by the American Petroleum Institute (API), suitable for use in high-temperature and high-pressure pipeline systems. Its special size and design enable it to meet the requirements of high pressure and high sealing performance in fields such as petroleum, chemical, and natural gas. The size of API 6A flange is relatively special, so when welding with pipelines, special interfaces or transition sections need to be set by the flange manufacturer to ensure that the wall thickness and outer diameter can match the ASME pipeline.

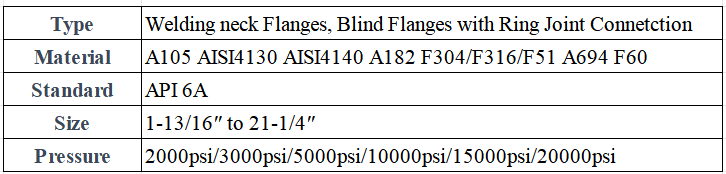

Dimensions&Pressure Ratings

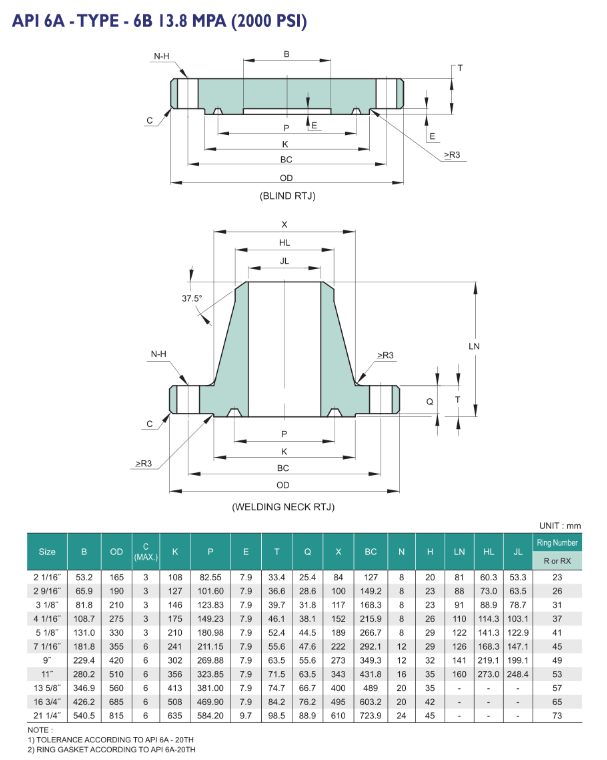

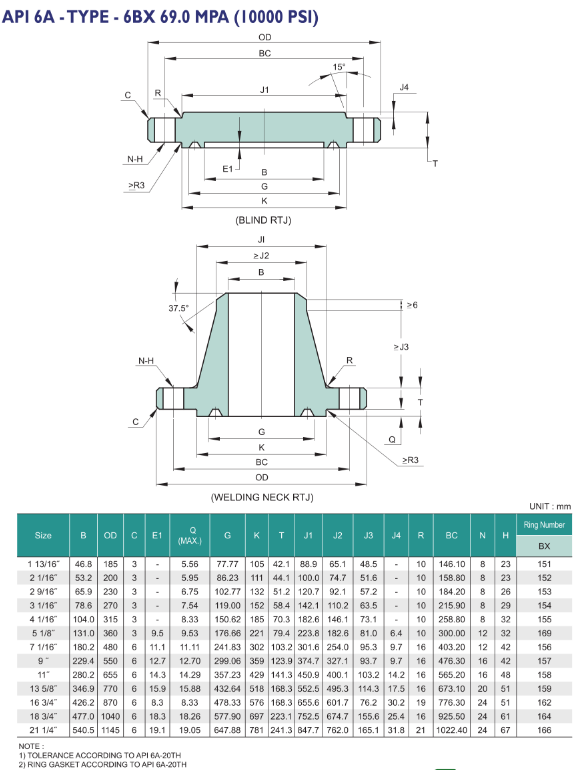

In terms of pressure rating, the API 6A flange has a wide range of pressure ratings, including but not limited to 13.8 MPa (2000 PSI), 20.7 MPa (3000 PSI), 34.5 MPa (5000 PSI), 69.0 MPa (10000 PSI), 103.5 MPa (15000 PSI), and 138.0 MPa (20000 PSI). Choosing the appropriate level of stress depends on the expected work pressure and work environment.

API 6A TYPE 6B 2000PSI Dimension

API 6A TYPE 6BX 10000PSI Dimension

API 6A Flange VS ASME Flange

Material and pressure rating: The material selection and pressure rating of API 6A flanges are higher than those of ASME flanges to adapt to higher operating pressures. This design makes API 6A flanges more suitable for high pressure working environments.

Size and interface: The size of API 6A flange is relatively special, and compared to ASME flange, its aperture size is larger. Therefore, when welding with pipelines, API 6A flanges need to be equipped with special interfaces or transition sections set by the flange manufacturer to ensure that their wall thickness and outer diameter can match the ASME pipeline. This design makes API 6A flanges more flexible and adaptable when connecting pipelines.

In addition, one type of API 6A flange, Type 6BX flange, requires the use of BX type gasket rings. The main difference between this type of gasket and ASME gasket is that there is a pressure through-hole on the section of the through ring, which can serve as a pressure self sealing seal. At the same time, the gasket also needs to use coatings and coatings to facilitate sealing and bonding, and there are specific requirements for the surface roughness of the gasket and groove to ensure sealing effectiveness.

Overall, there are significant differences between API 6A flanges and ASME flanges in terms of material, pressure rating, size, and interface design. The choice of flange to use depends on the specific working environment and engineering requirements.

In practical applications, it is necessary to consider various factors comprehensively, such as working pressure, pipeline connection requirements, sealing performance, etc., in order to choose the most suitable flange type. At the same time, it is also necessary to follow relevant standards and specifications to ensure the safety and reliability of flanges.