This purchase is a repeat order from our valued customer for ASTM A182 F316L blind flanges, consisting of one 2″ Class 600 raised face (RF) blind flange and five 1″ Class 600 raised face (RF) blind flanges. All products will be supplied in strict accordance with ASME B16.5 standards. Our ASTM A182 F316L blind flanges offer outstanding corrosion resistance, excellent mechanical strength, and reliable performance under high-pressure and high-temperature conditions, making them the ideal choice for your application. We are a reliable and professional manufacturer of high-quality flange products, covering weld neck flanges, blind flanges, socket weld flanges, and more. These products are extensively used in petroleum, natural gas, chemical, and power sectors. We places great emphasis on product quality and customer service, offering a complete range of products. Custom solutions are available upon request. Please feel free to contact us.

Product Descriptions

| Descriptions | Quantity | Unit |

| Model: FLBL; Material: F316L (ASTM A182); Flange Facing: Raised Face (RF); Pressure Rating: ASME Class 600; Size: 2″ | 100 | pcs |

| Model: FLBL; Material: F316L (ASTM A182); Flange Facing: Raised Face (RF); Pressure Rating: ASME Class 600; Size: 1″ | 50 | pcs |

ASTM A182 F316L Blind Flanges Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| A182 F316L Blind Flanges | 0.08 maximum | 2.0 maximum | 1.0 maximum | 0.045 maximum | 0.030 maximum | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 minimum |

ASTM A182 F316L Blind Flanges Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2% Offset) | Elongation |

| 8.0 g/cm³ | 1400 °C (2550 °F) | Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 35 % |

ASTM A182 F316L Blind Flanges Marking

The marking on ASTM A182 F316L blind flanges plays a vital role in ensuring product reliability and integrity. It not only confirms compliance with international standards but also facilitates easy on-site identification and installation. Additionally, it enables full traceability of materials and supports effective quality control throughout the product’s lifecycle.

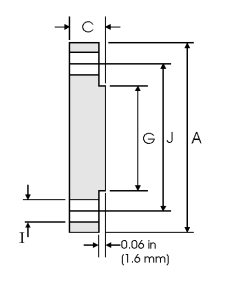

Class 150 lb Blind Flange Dimensions & Weight Chart

| NPS | A | C | G | H | I | J | W |

| inch | inch | inch | No. of holes | inch | inch | kg/pc | |

| mm | mm | mm | mm | mm | |||

| 1/2 | 3.500 | 0.440 | 1.380 | 4 | 0.620 | 2.380 | 0.42 |

| 88.90 | 11.20 | 35.10 | 15.70 | 60.45 | |||

| 3/4 | 3.880 | 0.500 | 1.690 | 4 | 0.620 | 2.750 | 0.61 |

| 98.60 | 12.70 | 42.90 | 15.70 | 69.85 | |||

| 1 | 4.250 | 0.560 | 2.000 | 4 | 0.620 | 3.120 | 0.86 |

| 108.0 | 14.20 | 50.80 | 15.70 | 79.25 | |||

| 1-1/4 | 4.620 | 0.620 | 2.500 | 4 | 0.620 | 3.500 | 1.17 |

| 117.3 | 15.70 | 63.50 | 15.70 | 88.90 | |||

| 1-1/2 | 5.000 | 0.690 | 2.880 | 4 | 0.620 | 3.880 | 1.53 |

| 127.0 | 17.50 | 73.15 | 15.70 | 98.60 | |||

| 2 | 6.000 | 0.750 | 3.620 | 4 | 0.750 | 4.750 | 2.42 |

| 152.4 | 19.10 | 91.90 | 19.10 | 120.7 | |||

| 2-1/2 | 7.000 | 0.880 | 4.120 | 4 | 0.750 | 5.500 | 3.94 |

| 177.8 | 22.40 | 104.6 | 19.10 | 139.7 | |||

| 3 | 7.500 | 0.940 | 5.000 | 4 | 0.750 | 6.000 | 4.93 |

| 190.5 | 23.90 | 127.0 | 19.10 | 152.4 | |||

| 3-1/2 | 8.500 | 0.940 | 5.500 | 8 | 0.750 | 7.000 | 6.17 |

| 215.9 | 23.90 | 139.7 | 19.10 | 177.8 | |||

| 4 | 9.000 | 0.940 | 6.190 | 8 | 0.750 | 7.500 | 7.00 |

| 228.6 | 23.90 | 157.2 | 19.10 | 190.5 | |||

| 5 | 10.00 | 0.940 | 7.310 | 8 | 0.880 | 8.500 | 8.63 |

| 254.0 | 23.90 | 185.7 | 22.40 | 215.9 | |||

| 6 | 11.00 | 1.000 | 8.500 | 8 | 0.880 | 9.500 | 11.3 |

| 279.4 | 25.40 | 215.9 | 22.40 | 241.3 | |||

| 8 | 13.50 | 1.120 | 10.62 | 8 | 0.880 | 11.75 | 19.6 |

| 342.9 | 28.40 | 269.7 | 22.40 | 298.5 | |||

| 10 | 16.00 | 1.190 | 12.75 | 12 | 1.000 | 14.25 | 28.8 |

| 406.4 | 30.20 | 323.9 | 25.40 | 362.0 | |||

| 12 | 19.00 | 1.250 | 15.00 | 12 | 1.000 | 17.00 | 43.2 |

| 482.6 | 31.75 | 381.0 | 25.40 | 431.8 | |||

| 14 | 21.00 | 1.380 | 16.25 | 12 | 1.120 | 18.75 | 58.1 |

| 533.4 | 35.10 | 412.8 | 28.40 | 476.3 | |||

| 16 | 23.50 | 1.440 | 18.50 | 16 | 1.120 | 21.25 | 76.0 |

| 596.9 | 36.60 | 469.9 | 28.40 | 539.8 | |||

| 18 | 25.00 | 1.560 | 21.00 | 16 | 1.250 | 22.75 | 93.7 |

| 635.0 | 39.60 | 533.4 | 31.75 | 577.9 | |||

| 20 | 27.50 | 1.690 | 23.00 | 20 | 1.250 | 25.00 | 122 |

| 698.5 | 42.90 | 584.2 | 31.75 | 635.0 | |||

| 24 | 32.00 | 1.880 | 27.25 | 20 | 1.380 | 29.50 | 185 |

| 812.8 | 47.80 | 692.2 | 35.10 | 749.3 |