We manufacture high-quality ASTM A213 seamless alloy steel tubes, in accordance with the ASTM A213 Standard Specification for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes. It has excellent high-temperature, corrosion, and pressure resistance, making it ideal for high-temperature, high-pressure environments like boilers, superheaters, and heat exchangers.

We specialize in manufacturing various types of seamless pipes, including precision tubes, heat exchanger tubes, petroleum cracking pipes, nuclear power pipes, and marine seamless pipes. We also offer pipe fittings such as bend, elbow, flanges, tees, etc. We have an advanced physical and chemical testing center and has established a comprehensive quality assurance system based on international and domestic standards, including ASME/ASTM (USA), JIS (Japan), DIN (Germany), EN (EU), and GB/NB (China). Feel free to contact us.

ASTM A213 Seamless Alloy Steel Pipe Scope

This standard covers seamless ferritic and austenitic steel tubes used in boilers, superheaters, and heat exchangers, including grades such as T5 and TP304. The pipe sizes range from an inside diameter of 1/8 inch (3.2 mm) to an outside diameter of 5 inches (127 mm), with wall thicknesses from 0.015 to 0.500 inches (0.4 to 12.7 mm). Custom sizes are also available upon request. Special requirements: Grades that include an “h” in their designation have different specifications compared to those without the “h”, offering superior creep rupture strength.

ASTM A213 Seamless Alloy Steel Pipe Specification

| A213 Alloy Steel Seamless Tubes Specification | ASTM A213/ASME SA213 |

| A213 Alloy Steel Seamless Tubes Grades | ASTM A213 T5, T9, T11, T22, T91 |

| A213 Alloy Steel Seamless Tubes Type | Seamless-Hot Rolled/Cold Drawn |

| A213 Alloy Steel Seamless Tubes Outer Diameter Size | A335-3/8″NB to 30″NB(Nominal Bore Size) |

| A213 Alloy Steel Seamless Tubes Wall Thickness | Schedule 20 – XXS(Heavier On Request) |

| A213 Alloy Steel Seamless Tubes Length | 5 to 7 Meters, 09 to 13 Meters, or per customer needs. |

| A213 Alloy Steel Seamless Tubes Pipe Ends | Plain Ends/Beveled Ends/Coupling |

| Tests | Tensile test, Flattening test, Flaring test, Hardness test, Nondestructive testing or hydraulic pressure test, Mechanical property test, Nondestructive test. |

| Product Marking | The steel pipes should be marked with details like the standard code, steel grade, size specifications, production details, heat number, etc., so as to facilitate traceability and quality management. |

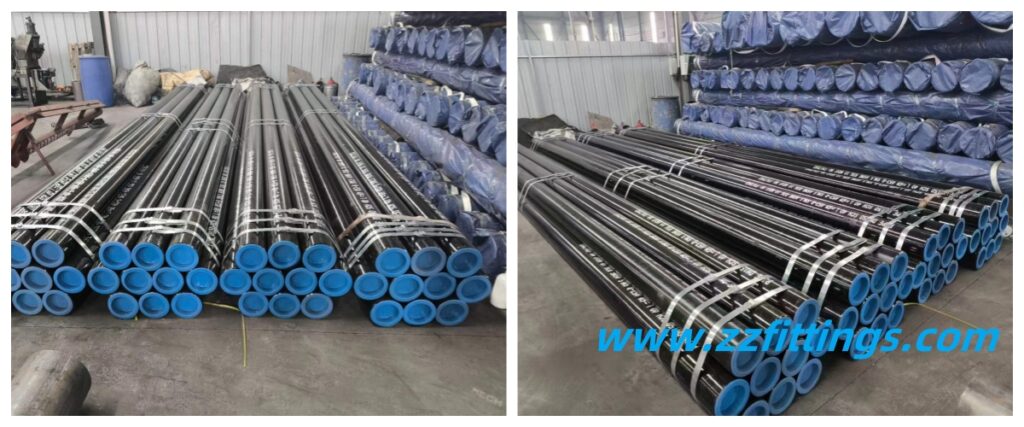

ASTM A213 Seamless Alloy Steel Pipe Manufacturer

We are a professional and trustworthy manufacturer and supplier of ASTM A213 seamless tubes. We specialize in manufacturing ASTM A213 seamless tubes in various grades and specifications, With years of experience, we guarantee stable product quality. Feel free to contact us anytime.

ASTM A213 Seamless Alloy Steel Pipe Grades and Application

ASTM A213 T9: It is widely used in boiler superheaters, reheaters.

ASTM A213 T11: It is widely used in industrial boilers, high-pressure pipelines.

ASTM A213 T12: It is widely used in petrochemical pipelines.

ASTM A213 T22: It is widely used in oil, chemical, power, aerospace equipment.

ASTM A213 T91: It is widely used in high-temperature components in thermal and nuclear power plants.

ASTM A213 Seamless Alloy Steel Pipe Features

Excellent high-temperature performance

High resistance to corrosion

Good pressure resistance

Good workability

Wide range of application fields

ASTM A213 Seamless Alloy Steel Pipe Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo |

| ASTM A213 T5 | MIN | 0.30 | 4.00 | 0.450 | ||||

| MAX | 0.150 | 0.60 | 0.025 | 0.025 | 0.50 | 6.00 | 0.650 | |

| ASTM A213 T9 | MIN | 0.30 | 0.25 | 8.00 | 0.900 | |||

| MAX | 0.150 | 0.60 | 0.025 | 0.025 | 1.00 | 10.00 | 1.100 | |

| ASTM A213 T11 | MIN | 0.050 | 0.30 | 0.50 | 1.00 | 0.440 | ||

| MAX | 0.150 | 0.60 | 0.025 | 0.025 | 1.00 | 1.50 | 0.650 | |

| ASTM A213T12 | MIN | 0.050 | 0.30 | 0.80 | 0.440 | |||

| MAX | 0.150 | 0.61 | 0.025 | 0.025 | 0.50 | 1.25 | 0.650 | |

| ASTM A213 T21 | MIN | 0.050 | 0.30 | 2.65 | 0.800 | |||

| MAX | 0.150 | 0.60 | 0.025 | 0.025 | 0.50 | 3.35 | 1.060 | |

| ASTM A213 T22 | MIN | 0.050 | 0.30 | 1.90 | 0.870 | |||

| MAX | 0.150 | 0.60 | 0.025 | 0.025 | 0.50 | 2.60 | 1.130 | |

| ASTM A213 T91 | MIN | 0.070 | 0.30 | 0.20 | 8.00 | 0.850 | ||

| MAX | 0.140 | 0.60 | 0.020 | 0.010 | 0.50 | 9.50 | 1.050 |

ASTM A213 Seamless Alloy Steel Pipe Mechanical Properties

| Steel Grade | Mechanical Properties | |||

| T. S | Y. P | Elongation | Hardness | |

| T2 | ≥ 415MPa | ≥ 205MPa | ≥ 30% | 163HBW(85HRB) |

| T11 | ≥ 415MPa | ≥ 205MPa | ≥ 30% | 163HBW(85HRB) |

| T12 | ≥ 415MPa | ≥ 220MPa | ≥ 30% | 163HBW(85HRB) |

| T22 | ≥ 415MPa | ≥ 205MPa | ≥ 30% | 163HBW(85HRB) |

| T91 | ≥ 585MPa | ≥ 415MPa | ≥ 20% | 250HBW(25HRB) |

| T92 | ≥ 620MPa | ≥ 440MPa | ≥ 20% | 250HBW(25HRB) |

ASTM A213 Seamless Alloy Steel Pipe Heat Treatment

| Grade | UNS Number | Heat Treat Type | Austenitizing/Solutioning Temperature, min or range °F [°C] | Cooling Media | Subcritical Annealing or Tempering Temperature, min or range °F [°C] |

| T5 | K11547 | Full or isothermal annealnormalize and tempersubcritical anneal | – | – | 1200 to 1350 [650 to 730] |

| T9 | K90941 | Full or isothermal annealnormalize and tempersubcritical anneal | – | – | 1250 [675] |

| T11 | K11597 | Full or isothermal annealnormalize and tempersubcritical anneal | – | – | 1200 [650] |

| T12 | K11562 | Full or isothermal annealnormalize and tempersubcritical anneal | – | – | 1200 to 1350 [650 to 730] |

| T21 | K31545 | Full or isothermal annealnormalize and tempersubcritical anneal | – | – | – |

| T22 | K21590 | Full or isothermal annealnormalize and tempersubcritical anneal | – | – | 1250 [675] |

| T91 | K90901 | normalize and temper | 1900 – 1975 [1040 – 1080] | – | 1350 – 1470 [730 – 800] |

ASTM A213 Seamless Alloy Steel Pipe Tensile and Hardness Requirements

| Grade | UNS Designation | TensileStrengthmin, kesi[MPa] | YieldStrength,min, ksi[MPa] | Elongationin 2 in. or50 mm.min, | Hardness | |

| Brinell/vickers | Rockwell | |||||

| Low Alloy Steels: | ||||||

| TSb | KS1545 | 60[415] | 30[205] | 30 | 179 HBW/190HV | 89 HRB |

| T9 | K90941 | 60[415] | 30[205] | 30 | 179 HBW/190HV | 89 HRB |

| T12 | K11562 | 60[415] | 32[220] | 30.00 | 163 HBW/170 HV | 85 HRB |

| T23 | K40712 | 74[510] | 58[400] | 20 | 220 HBW/230 HV | 97 HRB |

| T24 | K30736 | 85[585] | 60[415] | 20.00 | 250 HBW/265 HV | 25 HRC |

| T91 | K90901 | 85 [585] | 60 [415] | 20 | 190 to 250 HBW/196 to 265 HV | 90 HRB to 25 HRC |

ASTM A213 Seamless Alloy Steel Pipe Outside Diameter and Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤190.5 | +0.4/-1.2 | |

| 190.5<OD≤228.6 | +0.4/-1.6 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, mm |

| OD<25.4 | ±0.10 | |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤190.5 | +0.38/-0.64 | |

| 190.5<OD≤228.6 | +0.38/-1.14 |

ASTM A213 Seamless Alloy Steel Pipe Wall Thickness and Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, % |

| OD≤38.1 | +20/-0 | |

| OD>38.1 | +22/-0 |

ASTM A213 Seamless Alloy Steel Pipe Development Trend

1. Higher Quality

Our ASTM A213 steel pipes will be improved by advancing technologies such as smelting, rolling, and heat treatment, boosting their mechanical, corrosion-resistant, and processing qualities.

2. Larger Sizes

With increasing energy demand and the trend toward larger equipment, our ASTM A213 steel pipes will develop into larger sizes, improving production efficiency, reducing costs, and enhancing energy efficiency.

3. Energy-saving and Green Production

The development of energy-saving techniques and the use of environmentally friendly materials in our production processes will help lower production costs and reduce environmental impact, making our ASTM A213 steel pipes more competitive in the market.