P11 alloy steel pipes are a high-temperature ferritic alloy steel pipe.Include in the American material standard ASTM A335.It has a chemical composition including elements such as carbon, manganese, phosphorus, sulfur, silicon, chromium, and molybdenum. This type of steel pipe has high strength and good corrosion resistance, and is mainly used in pipeline systems in high-temperature and high-pressure environments.

ASTM A335 Material Standard

ASTM A335 material standard includes various common alloy materials such as P11, P22, P12, P9, P5, P92, etc. The production standard is executed according to the American standard ASME B36.10M.

ASTM A335 alloy steel pipes have strict requirements for the type of steel used in the manufacture of steel pipes. Its mechanical properties such as tensile strength, yield strength, and elongation after fracture all meet certain standards.

In the manufacturing process, the raw materials for seamless alloy pipes are mainly composed of metal powder and additives. After mixing the alloy ratio and raw materials, they are placed in a high-temperature alloying reaction furnace under a vacuum atmosphere for reaction, and then cast into shape. Subsequently, the alloy billet undergoes steps such as heat treatment and cold processing to achieve the required special properties.

ASTM A335 P11 Alloy Steel Pipes properties

ASTM A335 P11 alloy steel pipes are widely used in pipeline systems. Its chemical composition is precisely proportioned, mainly including alloy elements such as carbon, manganese, phosphorus, sulfur, silicon, chromium, and molybdenum. These elements work together to give alloy steel pipes excellent comprehensive performance.

Chemical Composition

| C | Mn | P | S | Si | Cr | Mo | |

| MIN | 0.05 | 0.30 | 0.50 | 1.00 | 0.44 | ||

| MAX | 0.15 | 0.60 | 0.025 | 0.025 | 1.00 | 1.50 | 0.65 |

ASTM A335 P11 alloy steel pipes can still maintain their mechanical properties and chemical stability in high temperature environments. This makes it significantly advantageous in high-temperature working environments such as petroleum, chemical, and electricity, and can withstand long-term high-temperature effects without failure.

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A335 P11 | 415 min | 205 min | 30 min |

ASTM A335 alloy pipes are also known as chromium molybdenum alloy pipes because their chromium and molybdenum alloy element content is higher than that of ordinary carbon steel pipes. Chromium and molybdenum alloy elements can improve the overall strength, high temperature resistance, and corrosion resistance of alloy pipes.

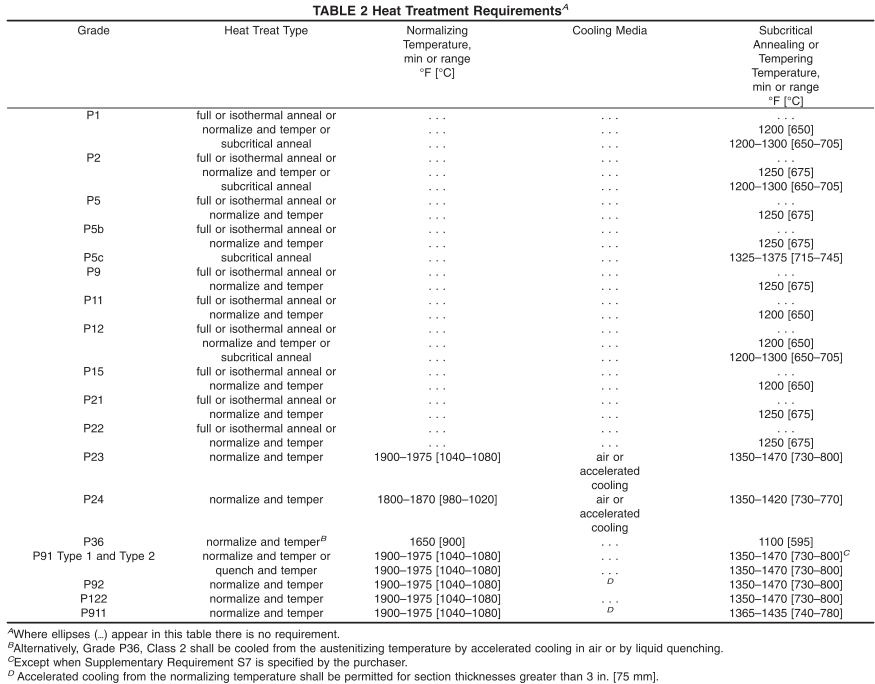

Heat Treatment

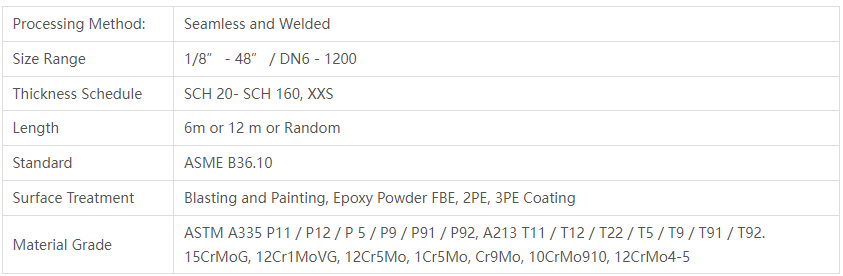

ASTM A335 P11 Alloy Steel Pipes Dimensions Specification

The size range of ASTM A335 P11 alloy steel pipes is wide, which can meet the needs of different industry applications. Its outer diameter is usually between 1/8 inch and 48 inches, while thick walls include specifications such as SCH 40, SCH STD, SCH 80, SCH XS, SCH 160, etc. In addition, according to specific application scenarios and customer needs, alloy steel pipes of other specific sizes can also be customized.

Application

In practical applications, ASTM A335 P11 alloy steel pipes are widely used in fields such as petroleum, chemical, power, and shipbuilding. Its high strength and good corrosion resistance enable it to work stably for a long time in high-temperature and high-pressure environments, making it suitable for fluid transportation in various complex environments.