- Home

- Blog Custom Layout

- Steel Pipe Caps

- Butt Weld On Pipe Cap

Butt Weld On Pipe Cap

USD9 USD8

6 Inch Sch 40 Weld On Pipe End Cap ASTM A234 WP9 ASME B16.9

- General Details

- Technical Info

- Specification

- Video

- Documents

- Related Products

Pipe End Cap Manufacturer

Zizi is a manufacturer and supplier of alloy steel weld on pipe end cap, top quality will be guaranteed by our skilled workers and professional technicians.

This fitting is design to use in moderate and high temperature service. Buttweld Pipe Caps are available in a wide range of dimensions and materials that are complied with national and international standards and grades.

Alloy Steel Buttweld Fittings

Why alloy steel A234 WP9 is prevalent for many fittings applications? We are sure it’s their advantage features.

- Resistant to rust and aqueous media.

- High tensile strength.

- Large application range.

- Long service life.

Weld On Metal Pipe Caps

Weld On Metal Pipe Caps

ASTM A403 WP304/304L, WP304H, WP316/316L, WP310, WP317, WP321

Duplex Steel BW Cap

ASTM A815 UNS S 31803, S 32205, S 32550, S 32750, S 32760

Carbon Steel End Cap

ASTM A234 WPB, A860 WPHY42, 52, 60, 65, 70

Low Temp Carbon Steel Cap

ASTM A420 WPL3, WPL6, WPL9

Alloy Steel Pipe Cap

ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

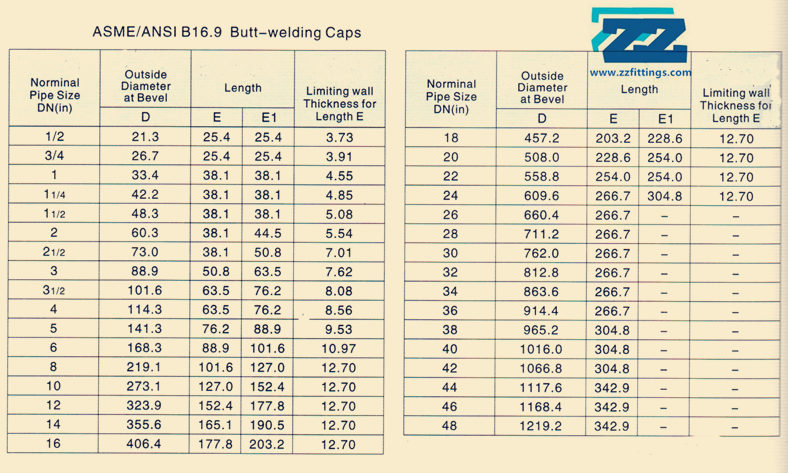

ASME B16.9 Cap Dimensions

ASME B16.9 Cap Dimensions

Standard: ASME/ANSI B16.9

Diameter: DN20 to DN1500/ 3/4″ to 60”

Thickness: Sch 10, 20, STD, 40, 80, 100, 120, 140, 160, XXS

Technical: Seamless and Weld Cap

Surface: Anti-rust Oil, Galvanized, Black Primer.

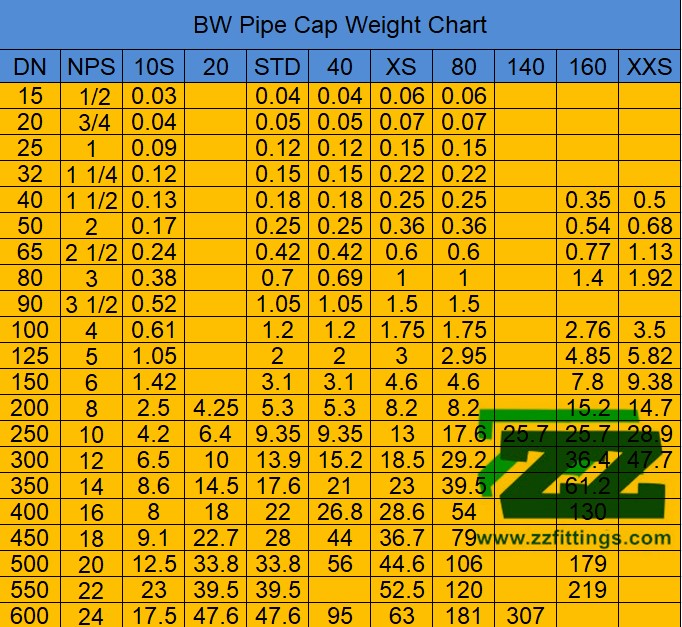

Pipe Cap Weight Chart

Pipe Cap Weight Chart

Low Alloy Steel Fittings

Package

We marked all A234 WP9 Buttweld Fittings with Grade, Lot No, Size, Standard and Schedule Thickness. Our workers wrapped 6 Inch Weld on Pipe Cap with water-proof material then packed them into wooden cases or pallets.

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. Great care is taken during operation and transportation.

Inspection

- Visual the surface of pipe cap body. Such as dents, die marks, porosity, undercuts.

- Check the marking. Such as size, material code, grade, thickness, heat no.

- Measure the dimensions. Such as diameter, thickness, height from end to end.

- Test the chemical properties of alloy steel pipe fittings.

Advantages

- Good Quality

- Fast Delivery

- Safe Package

- Abundant Stock

- Reasonable Price

- Reliable Shipment

ASTM A234 WP91

Chemical Composition, %

| C | Si | Mn | S | P | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.15 | 1.00 | 0.6 | 0.03 | 0.03 | 8-10 | 0.9-1.1 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 585 (Mpa) | 380 (Mpa) | 30 (%) |

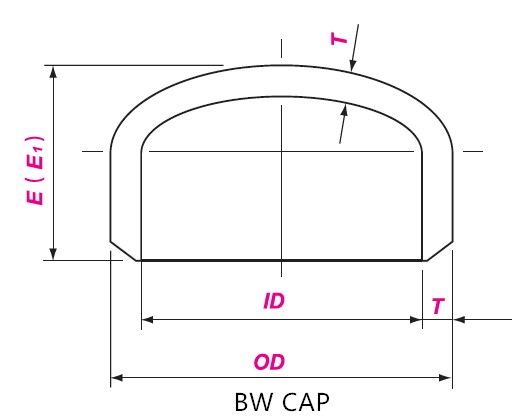

BW CAP DRAWING & SPECIFICATION

Butt Weld Cap Drawing

Note:

1)The configuration of the cap is normal ellipse.

2)Length E applies for the thickness not exceeding the Limiting Wall Thickness, Length E1 applies for the thickness exceeding the Limiting Wall Thickness.For the caps with DN ≥650 (NPS26), they will be made subject to the sizes agreed between purchaser and manufacturer or be supplied according to manufacturer’s size.

| Nominal Size | Outside Diameter at Bevel |

Length | Limiting Wall Thickness for Length E |

||

|---|---|---|---|---|---|

| DN | NPS | OD | E | E1 | |

| 15 | 1/2 | 21.3 | 25 | 25 | 4.57 |

| 20 | 3/4 | 26.7 | 25 | 25 | 3.81 |

| 25 | 1 | 33.4 | 38 | 38 | 4.57 |

| 32 | 1 1/4 | 42.2 | 38 | 38 | 4.83 |

| 40 | 1 1/2 | 48.3 | 38 | 38 | 5.08 |

| 50 | 2 | 60.3 | 38 | 44 | 5.59 |

| 65 | 2 1/2 | 73 | 38 | 51 | 7.11 |

| 80 | 3 | 88.9 | 51 | 64 | 7.62 |

| 90 | Feb-31 | 101.6 | 64 | 76 | 8.13 |

| 100 | 4 | 114.3 | 64 | 76 | 8.64 |

| 125 | 5 | 141.3 | 76 | 89 | 9.65 |

| 150 | 6 | 168.3 | 89 | 102 | 10.92 |

| 200 | 8 | 219.1 | 102 | 127 | 12.7 |

| 250 | 10 | 273 | 127 | 152 | 12.7 |

| 300 | 12 | 323.8 | 152 | 178 | 12.7 |

| 350 | 14 | 355.6 | 165 | 191 | 12.7 |

| 400 | 16 | 406.4 | 178 | 203 | 12.7 |

| 450 | 18 | 457 | 203 | 229 | 12.7 |

| 500 | 20 | 508 | 229 | 254 | 12.7 |

| 550 | 22 | 559 | 254 | 254 | 12.7 |

| 600 | 24 | 610 | 267 | 305 | 12.7 |

| 650 | 26 | 660 | 267 | — | — |

| 700 | 28 | 711 | 267 | — | — |

| 750 | 30 | 762 | 267 | — | — |

| 800 | 32 | 813 | 267 | — | — |

| 850 | 34 | 864 | 267 | — | — |

| 900 | 36 | 914 | 267 | — | — |

| 950 | 38 | 965 | 305 | — | — |

| 1000 | 40 | 1016 | 305 | — | — |

| 1050 | 42 | 1067 | 305 | — | — |

| 1100 | 44 | 1118 | 343 | — | — |

| 1150 | 46 | 1168 | 343 | — | — |

| 1200 | 48 | 1219 | 343 | — | — |

8 Inch Pipe Cap A403 WP304

8 Inch Steel Pipe Cap Sch40S Seamless BW ASTM A403 WP304 ASME B16.9

USD37 USD36