- Home

- Blog Custom Layout

- Steel Pipe Bends

- A234 WP91 Steel Bend

A234 WP91 Steel Bend

USD610 USD588

90 Degree Bend R = 3D BW DN400 Sch 40 ASTM A234 WP91 ASME B16.9

- General Details

- Technical Info

- Dimensions

- Related Products

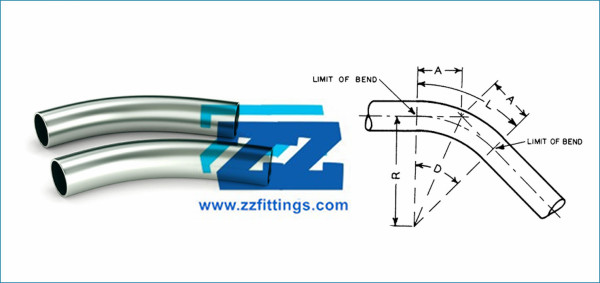

Zizi manufacture an extensive range of alloy steel pipe bends and export quantities of ASTM A234 WP91 90Degree 3D Bend for industries in attractive price. It is almost same as pipe elbow. It’s radius is bigger and extensive used in oil and gas, engineering and construction industry.

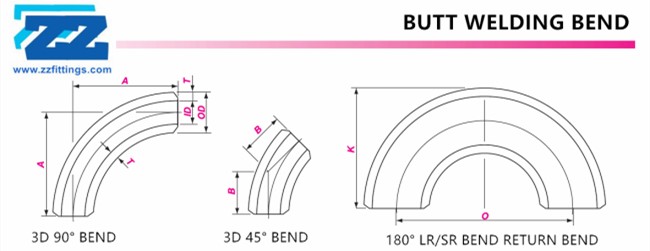

Steel Pipe Bends Dimensions

Steel Pipe Bends Dimensions

Size: 1/2″ to 48″

Thickness: Sch 10s, 20, STD, 40S, XS, 80S, 120, 160

Standard: DL/T515, SY5257, ASME B16.9 or customer’s technical drawings

Bend Radius R: R = 3D, 4D, 5D, 6D, 7D, 8D, 9D, 10D

Bend Angle: 15°, 30°, 45°, 60°, 90°, 135°, 180° or at customer’s option

Straight Length L: Usually between 300mm and 1500mm

Carbon Steel Grades: ASTM A234 WPB, A860 WPHY42, WHPY52, WPHY60, WHPY65, WPHY70, ASTM A420 WPL3,WPL6, WPL9

Stainless Steel Grades: ASTM A403 WP304/304L, WP304H, WP316/316L, WP310, WP317, WP321, WP309

Duplex Stainless Steel Grades: ASTM A815 UNS S 31803, S 32205, S 32550, S 32750, S 32760

Alloy Steel Material & Grades: ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Alloy Steel Pipe Bend Weight Calculator

Weight Formula =0.0387 * S( D – S ) * R / 1000

- W = Weight (kg/piece).

- S = Thickness in mm.

- D = Outside Diameter in mm

- R= Radius = 3 D, 5D and etc.

3D Bend Weight Chart

This weight chart is available in 3D 90 Degree Bend from 1/2″ to 24″. The normal thickness Schedule 40, XS, 80 and 160.

| DN | NPS | 40 | XS | 80 | 160 |

|---|---|---|---|---|---|

| 15 | 1/2 | 0.2 | 0.22 | 0.22 | 0.3 |

| 20 | 3/4 | 0.33 | 0.43 | 0.43 | 0.6 |

| 25 | 1 | 0.56 | 0.48 | 0.48 | 1 |

| 32 | 1 1/4 | 0.8 | 1.1 | 1.1 | 1.5 |

| 40 | 1 1/2 | 1.4 | 2 | 2 | 3 |

| 50 | 2 | 2.8 | 3.75 | 3.75 | 5 |

| 65 | 2 1/2 | 4.5 | 6 | 6 | 8.5 |

| 80 | 3 | 6.3 | 8.6 | 8.6 | – |

| 90 | 3 1/2 | 8.5 | 11.8 | 11.8 | 17.7 |

| 100 | 4 | 14.3 | 20.4 | 20.4 | 32.3 |

| 125 | 5 | 22.3 | 33.6 | 33.6 | 53.5 |

| 150 | 6 | 45 | 68.1 | 68.1 | 117 |

| 200 | 8 | 79.5 | 107 | 126 | 227 |

| 250 | 10 | 126 | 154 | 209 | 377 |

| 300 | 12 | 174 | 198 | 292 | 519 |

| 350 | 14 | 260 | 260 | 429 | 770 |

| 400 | 16 | 369 | 330 | 604 | 1089 |

| 450 | 18 | 483 | 409 | 8109 | 1487 |

| 500 | 20 | – | 496 | 1083 | 1947 |

| 550 | 22 | 807 | 591 | 1397 | 2554 |

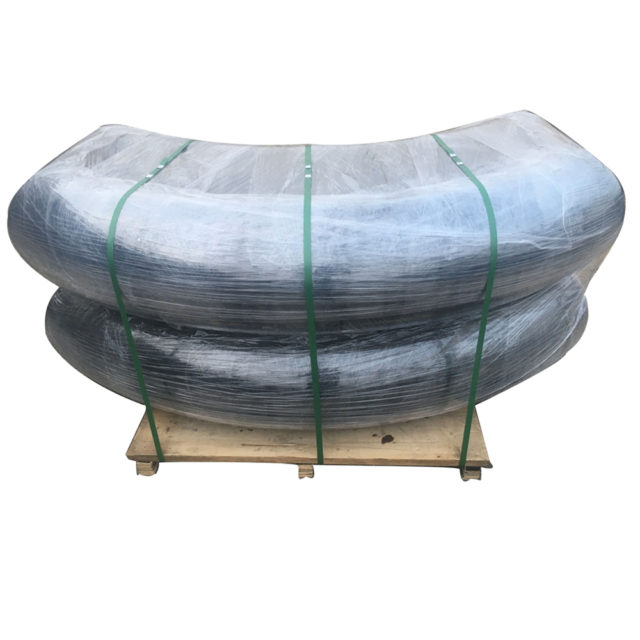

How to Pack Alloy Steel Buttweld Fittings

All Alloy Steel Buttweld Fittings are marked with Grade, Lot No, Size, Standard and Thickness. ASTM A234 WP91 Steel Bend is packed into wooden pallets.

ASTM A234 WP91 Steel Bend Package

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. great care is taken during operation and transportation.

How Inspect Steel Pipe Bend

Visual the surface of steel pipe bend body.

Check the marking if covering all necessary information.

Measure outside diameter, wall thickness, radius of alloy steel bends.

Alloy Steel Features

Hardenability

Strength

Formability

Weldability

Ductility

Corrosion resistance

ASTM A234 GRADE WP91

Chemical Composition

| C | Mn | Si | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.08-0.12 | 0.3-0.6 | 0.2-0.5 | 0.015 | 0.02 | 8-9.5 | 0.85-1.05 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 590 (Mpa) | 415 (Mpa) | 20 (%) |

3D Bend Dimensions

3D BEND DIMENSIONS

| Nominal Size | Outside Diameter at Bevel |

Center to End | Center to Center | Back to Face | ||||

| 90Elbows | 45Elbows | 180Returns | ||||||

| DN | NPS | OD | A | B | O | K | ||

| 3D | 3D | LR | SR | LR | SR | |||

| 15

20 25 |

1/2

3/4 1 |

21.3

26.7 33.4 |

–

57 76 |

–

24 31 |

76

76 76 |

–

– 51 |

48

51 56 |

–

– 41 |

| 32

40 50 |

11/4

11/2 2 |

42.2

48.3 60.3 |

95

114 152 |

39

47 63 |

95

114 152 |

64

76 102 |

70

83 106 |

52

62 81 |

| 65

80 90 100 |

21/2

3 31/2 4 |

73.0

88.9 101.6 114.3 |

190

229 267 305 |

79

95 111 127 |

190

229 267 305 |

127

152 178 203 |

132

159 184 210 |

100

121 140 159 |

| 125

150 200 |

5

6 8 |

141.3

168.3 219.1 |

381

457 610 |

157

189 252 |

381

457 610 |

254

305 406 |

262

313 414 |

197

237 313 |

| 250

300 350 |

10

12 14 |

273.0

323.8 355.6 |

762

914 1067 |

316

378 441 |

762

914 1067 |

508

609 711 |

518

619 711 |

391

467 533 |

| 400

450 500 |

16

18 20 |

406.4

457.0 508.0 |

1219

1372 1524 |

505

568 632 |

1219

1372 1524 |

813

914 1016 |

813

914 1016 |

610

686 762 |

| 550

600 650 |

22

24 26 |

559.0

610.0 660.0 |

1676

1829 1981 |

694

757 821 |

1676

1829 – |

1118

1219 – |

1118

1219 – |

838

914 – |

| 700

750 800 |

28

30 32 |

711.0

762.0 813.0 |

2134

2286 2438 |

883

964 1010 |

–

– – |

–

– – |

–

– – |

–

– – |

| 850

900 950 |

34

36 38 |

864.0

914.0 965.0 |

2591

2743 2896 |

1073

1135 1200 |

–

– – |

–

– – |

–

– – |

–

– – |

| 1000

1050 1100 |

40

42 44 |

1016.0

1067.0 1118.0 |

3048

3200 3353 |

1264

1326 1389 |

–

– – |

–

– – |

–

– – |

–

– – |

| 1150

1200 |

46

48 |

1168.0

1219.0 |

3505

3658 |

1453

1516 |

–

– |

–

– |

–

– |

–

– |

Stainless Steel Pipe Bends

90 Degree Bends 3D 12" Sch 40S ASTM A312 TP 316 ASME B36.19M

USD1550 USD1500

SS 316 Concentric Reducer

SS 316 Concentric Reducer 8" x 6" Sch 40S Seamless BW ASME B16.9

USD98 USD96

Galvanized 90 Degree Elbow

Galvanized 1 Inch BSPP 3000# 90 Degree Elbow ASTM A694 F52 ASME B16.11

USD6 USD5

45 Degree Long Radius Elbow

6” STD 45 Degree Long Radius Elbow Seamless ASTM A420 WPL6 ASME B16.9

USD8 USD7