- Home

- Blog Custom Layout

- Steel Pipe Bends

- Stainless Steel Pipe Bends

Stainless Steel Pipe Bends

USD1550 USD1500

90 Degree Bends 3D 12" Sch 40S ASTM A312 TP 316 ASME B36.19M

- General Details

- Technical Info

- DWG & SPEC

- Documents

- Related Products

Stainless steel pipe bends are available in 90 degree and 45 degree, while 3D and 5D bend pipe fittings are very common used in the industries.

As a reliable supplier of stainless steel pipe fittings, we offer 90 degree bends R=3D 12″ Sch 40S ASTM A312 TP316 ASME B36.19M in attractive price.

We can supply stainless steel butt weld fittings according to ASME, EN, DIN, JIS and GB standards. The major grades are SS 304/304L/304H and 316/316L. We can manufacture the size from 1/2″ to 48″ for elbows and bends, concentric and eccentric reducer, straight and reducing tee, cap and stub end.

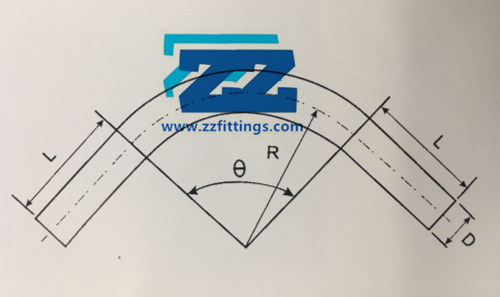

Weight Formula of Stainless Steel Pipe Bends

Drawings of Stainless Steel Pipe Bends

The weight formula: 0.0433 x (D-T) x T x R x θ / 100000 + L

- D = Outside Diameter

- T = Thickness

- R = Bend Radius

- θ = Bend Angle

- L = Weight of Double Sides Straight Length

What is Bend Radius and Angle for Steel Pipe Bending?

Usually R≥3D , such as R= 3D, 4D, 5D, 6D, 7D, 8D, 9D, 10D

Normally 15°, 30°, 45°, 60°, 90°, 135°, 180° or at customer’s option.

What is the Straight Length?

Normally straight length of pipe bends are between 300mm and 1500mm. Also can be customized as per customer’s requirements.

Material Grades for Steel Pipe Bends

Carbon Steel 90 Degree Bends

ASTM A234 WPB, A106B, A860 WPHY42, 52, 60, 65, 70, A420 WPL 3 / 6 / 9

Alloy Steel 45 Degree Bends

ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Stainless Steel Pipe Bends

ASTM A403 WP304/304L/304H, WP316/316L, WP310, WP317, WP321, WP309, WP347

Duplex Steel 180 Degree Bends

ASTM A815 UNS S 31803, 32205, 32550, 32750, 32760

How to Pack Large Diameter Pipe Fittings?

Package of 3D Bends

Marking ” 90° Bend 3D 12″ Sch 40S SS316 ASME B36.19 ZZ158″ on body.

Wrapping thin film on the stainless steel pipe fittings.

Packing them into the wooden cases or pallets.

Sticking the shipping marking on the outside of packages.

ASTM A312 TP 316 SPECIFICATION

Chemical Composition

| GRADE | C | MN | SI | P | S | CR | MO | NI | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 316 | Min | – | – | – | 0 | – | 16 | 2 | 10 | – |

| Max | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | 0.1 | |

| 316L | Min | – | – | – | – | – | 16 | 2 | 10 | – |

| Max | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | 0.1 | |

| 316H | Min | 0.04 | 0.04 | 0 | – | – | 16 | 2 | 10 | – |

| max | 0.1 | 0.1 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | – |

Mechanical Properties

| GRADE | TENSILE STRENGTH | YIELD STRENGTH | ELONGATION | HARDNESS | |

|---|---|---|---|---|---|

| (MPA) MIN | (MPA) MIN | (% IN 50MM) MIN | (HR B) MAX | (HB) MAX | |

| 316 | 515 | 205 | 40 | 95 | 217 |

| 316L | 485 | 170 | 40 | 95 | 217 |

| 316H | 515 | 205 | 40 | 95 | 217 |

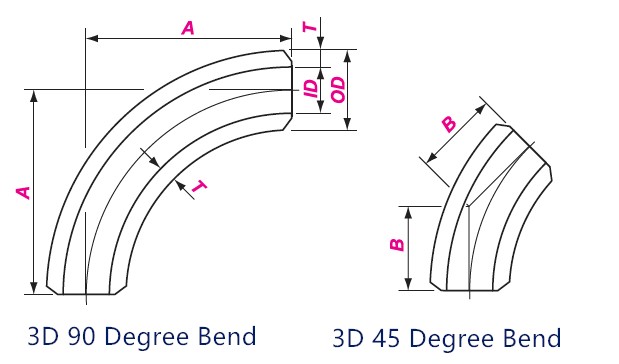

Drawing & Specification for Stainless Steel Pipe Bend

3D Bend Drawing

| Nominal Size | Center to End | Center to Center | Back to Face | |||||

|---|---|---|---|---|---|---|---|---|

| 90°Bend | 45°Bend | 180°Returns | ||||||

| DN | NPS | OD | A | B | O | K | ||

| 3D | 3D | LR | SR | LR | SR | |||

| 15 | 1/2 | 21.3 | 76 | 48 | ||||

| 20 | 3/4 | 26.7 | 57 | 24 | 76 | 51 | ||

| 25 | 1 | 33.4 | 76 | 31 | 76 | 51 | 56 | 41 |

| 32 | 1 1/4 | 42.2 | 95 | 39 | 95 | 64 | 70 | 52 |

| 40 | 1 1/2 | 48.3 | 114 | 47 | 114 | 76 | 83 | 62 |

| 50 | 2 | 60.3 | 152 | 63 | 152 | 102 | 106 | 81 |

| 65 | 2 1/2 | 73 | 190 | 79 | 190 | 127 | 132 | 100 |

| 80 | 3 | 88.9 | 229 | 95 | 229 | 152 | 159 | 121 |

| 90 | 3 1/2 | 101.6 | 267 | 111 | 267 | 178 | 184 | 140 |

| 100 | 4 | 114.3 | 305 | 127 | 305 | 203 | 210 | 159 |

| 125 | 5 | 141.3 | 381 | 157 | 381 | 254 | 262 | 197 |

| 150 | 6 | 168.3 | 457 | 189 | 457 | 305 | 313 | 237 |

| 200 | 8 | 219.1 | 610 | 252 | 610 | 406 | 414 | 313 |

| 250 | 10 | 273 | 762 | 316 | 762 | 508 | 518 | 391 |

| 300 | 12 | 323.8 | 914 | 378 | 914 | 609 | 619 | 467 |

| 350 | 14 | 355.6 | 1067 | 441 | 1067 | 711 | 711 | 533 |

| 400 | 16 | 406.4 | 1219 | 505 | 1219 | 813 | 813 | 610 |

| 450 | 18 | 457 | 1372 | 568 | 1372 | 914 | 914 | 686 |

| 500 | 20 | 508 | 1524 | 632 | 1524 | 1016 | 1016 | 762 |

| 550 | 22 | 559 | 1676 | 694 | 1676 | 1118 | 1118 | 838 |

| 600 | 24 | 610 | 1829 | 757 | 1829 | 1219 | 1219 | 914 |

| 650 | 26 | 660 | 1981 | 821 | ||||

| 700 | 28 | 711 | 2134 | 883 | ||||

| 750 | 30 | 762 | 2286 | 964 | ||||

| 800 | 32 | 813 | 2438 | 1010 | ||||

| 850 | 34 | 864 | 2591 | 1073 | ||||

| 900 | 36 | 914 | 2743 | 1135 | ||||

| 950 | 38 | 965 | 2896 | 1200 | ||||

| 1000 | 40 | 1016 | 3048 | 1264 | ||||

| 1050 | 42 | 1067 | 3200 | 1326 | ||||

| 1100 | 44 | 1118 | 3353 | 1389 | ||||

| 1150 | 46 | 1168 | 3505 | 1453 | ||||

| 1200 | 48 | 1219 | 3658 | 1516 | ||||

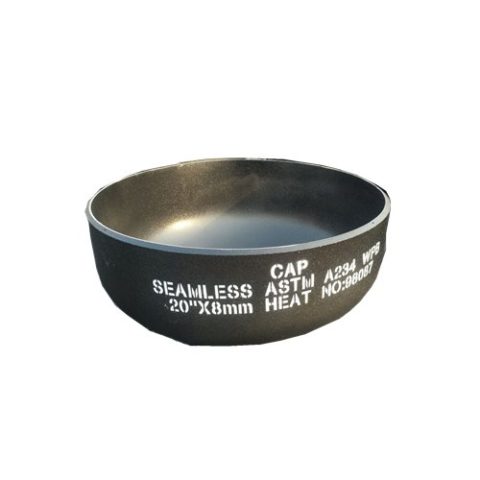

Large Diameter Steel Pipe Cap

Seamless Steel Pipe Cap BE 20" x 8mm BW ASTM A234 WPB ASME B16.9

USD50 USD48

Stainless Steel Eccentric Reducer

4"×3" Sch40S Stainless Steel Eccentric Reducer ASTM A403 WP304 ASME B16.9

USD15 USD13

ASTM A105 Reducing Tee Galvanized

Reducing Tee SW DN40 X DN32 Class 3000 Galvanized ASTM A105 ASME B16.11

USD19 USD18

A815 UNS S31803 Elbow Fittings

12" ELBOW 90 DEGREE LR SMLS ASME B16.9 ASTM A815 UNS S31803 SCH60

USD1516 USD1488