- Home

- Blog Custom Layout

- Steel Pipe Elbows

- Alloy Steel Elbow 90 Degree

Alloy Steel Elbow 90 Degree

USD460 USD450

90 Degree Elbow DN350 PN100 ASTM A234 WP12 ASME B16.9

- General Details

- Technical Info

- Specification

- Video

- Documents

- Related Products

We are manufacturer, exporter, supplier of alloy steel pipe fittings that offer 90 Degree Elbow DN350 PN100 ASTM A234 WP12 ASME B16.9 for Thailand.

They are made of best alloy steel which we buy from our most trusted and reliable steel mill. Alloy steel buttweld pipe fittings are basically concentric and eccentric reducers, equal and reducing tees, 90 degree elbow and bends, caps, stub ends. Which are available in different specifications of sizes and shapes.

90 Degree Elbow Dimensions

| Size | NPS 1/2 – 48 / DN15 – DN48 |

| Thickness | Sch 10S,20,STD,40,80,XS,120,160,XXS |

| Standard | GB/T12459,ASME B16.9,SH3408,HG/T21631, SY/T0510 |

| Surface | Blast and Painting, Anti-rust Oil |

| Package | Wooden Case or Pallets |

90 Degree Elbow Dimensions

Alloy Steel Elbow

ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Carbon Steel 90 Degree Elbow

ASTM A234 WPB, A860 WPHY42, 52, 60, 65, 70, A420 WPL 3 / 6 / 9

Stainless Steel Short Radius Elbow

ASTM A403 WP304/304L/304H, WP316/316L, WP310, WP317, WP321, WP347

Duplex Steel 45 Degree Elbow

ASTM A815 UNS S 31803, 32205, 32550, 32750, 32760

RFQ of Alloy Steel Elbow

How to Recognize ASTM A234 WP12 Elbow Easily?

We will do the marking ” 90 ELBOW LR DN350 PN100 A234 WP12 ASME B16.9 ZZ188″ on the body of fittings.

What is Export Package for Alloy Steel Pipe Fittings?

- Blasting and Painting on pipe fittings.

- Wrapping them with plastic foam.

- Packing them into wooden case or pallet.

- Stick shipping mark on the outside of wooden case.

Standard Schedule Elbow Weight

| DN | NPS | STD |

| 15 | 1/2 | 0.08 |

| 20 | 3/4 | 0.11 |

| 25 | 1 | 0.15 |

| 32 | 1 1/4 | 0.25 |

| 40 | 1 1/2 | 0.39 |

| 50 | 2 | 0.66 |

| 65 | 2 1/2 | 1.37 |

| 80 | 3 | 2.19 |

| 90 | 3 1/2 | 2.96 |

| 100 | 4 | 4.13 |

| 125 | 5 | 6.89 |

| 150 | 6 | 10.7 |

| 200 | 8 | 21.6 |

| 250 | 10 | 37 |

| 300 | 12 | 56 |

| 350 | 14 | 71.4 |

| 400 | 16 | 93.6 |

| 450 | 18 | 119 |

| 500 | 20 | 147 |

| 550 | 22 | 178 |

| 600 | 24 | 212 |

How to Guarantee the Quality of Alloy Steel 90 Degree Elbow?

Visual the surface of buttweld elbow body. Such as dents, die marks, porosity, undercuts.

Check the marking. Such as size, type, grade, thickness, heat No.

Measure the dimensions. Such as diameter, thickness.

Test the chemical properties of alloy steel pipe fittings.

Why Choose US for Alloy Steel Buttweld Fittings?

ISO Certified Quality

CE Certified Manufacturer

Fast Delivery

Safe Package

Abundant Stock

Reasonable Price

Properties of Alloy Steel Buttweld Fittings

| Grade | C | Mn | Si | S | P | Cr | Mo |

|---|---|---|---|---|---|---|---|

| A234WP12 | 0.05-0.2 | ≤0.6 | ≤0.45 | ≤0.04 | ≤0.03 | 0.8-1.25 | 0.44-0.65 |

| A234WP5 | ≤0.15 | ≤0.6 | ≤0.5 | ≤0.04 | ≤0.03 | 4.0-6.0 | 0.44-0.65 |

| A234WP11 | 0.05-0.2 | 0.3-0.8 | 0.5-1 | ≤0.030 | ≤0.030 | 1-1.5 | 0.44-0.65 |

| A234WP22 | 0.05-0.15 | 0.3-0.6 | ≤0.5 | ≤0.04 | ≤0.04 | 2-2.5 | 0.87-1.13 |

| A234WP91 | 0.08-0.12 | 0.3-0.6 | 0.2-0.5 | ≤0.02 | ≤0.015 | 8-9.5 | 0.85-1.05 |

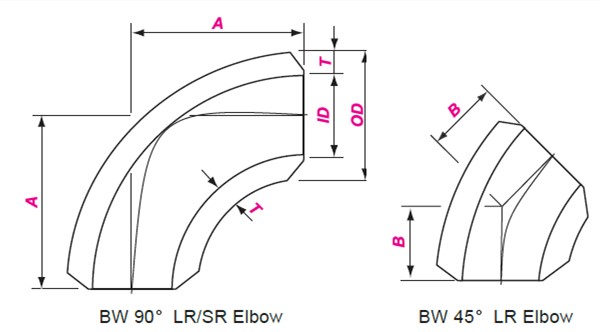

Drawing & Specification for Alloy Steel Elbow

BW Alloy Steel Elbow Drawing

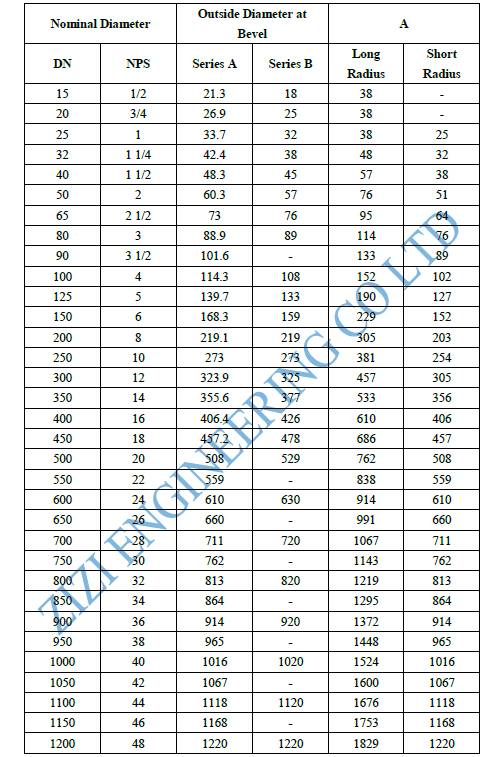

| Nominal Diameter | Outside Diameter at Bevel | A | B | ||

|---|---|---|---|---|---|

| DN | NPS | OD | Long Radius | Short Radius | Long Radius |

| 15 | 1/2 | 21.3 | 38 | – | 16 |

| 20 | 3/4 | 26.9 | 38 | – | 19 |

| 25 | 1 | 33.7 | 38 | 25 | 22 |

| 32 | 1 1/4 | 42.4 | 48 | 32 | 25 |

| 40 | 1 1/2 | 48.3 | 57 | 38 | 29 |

| 50 | 2 | 60.3 | 76 | 51 | 35 |

| 65 | 2 1/2 | 73 | 95 | 64 | 44 |

| 80 | 3 | 88.9 | 114 | 76 | 51 |

| 90 | 3 1/2 | 101.6 | 133 | 89 | 57 |

| 100 | 4 | 114.3 | 152 | 102 | 64 |

| 125 | 5 | 139.7 | 190 | 127 | 79 |

| 150 | 6 | 168.3 | 229 | 152 | 95 |

| 200 | 8 | 219.1 | 305 | 203 | 127 |

| 250 | 10 | 273 | 381 | 254 | 159 |

| 300 | 12 | 323.9 | 457 | 305 | 190 |

| 350 | 14 | 355.6 | 533 | 356 | 222 |

| 400 | 16 | 406.4 | 610 | 406 | 254 |

| 450 | 18 | 457.2 | 686 | 457 | 286 |

| 500 | 20 | 508 | 762 | 508 | 318 |

| 550 | 22 | 559 | 838 | 559 | 343 |

| 600 | 24 | 610 | 914 | 610 | 381 |

| 650 | 26 | 660 | 991 | 660 | 406 |

| 700 | 28 | 711 | 1067 | 711 | 438 |

| 750 | 30 | 762 | 1143 | 762 | 470 |

| 800 | 32 | 813 | 1219 | 813 | 502 |

| 850 | 34 | 864 | 1295 | 864 | 533 |

| 900 | 36 | 914 | 1372 | 914 | 565 |

| 950 | 38 | 965 | 1448 | 965 | 600 |

| 1000 | 40 | 1016 | 1524 | 1016 | 632 |

| 1050 | 42 | 1067 | 1600 | 1067 | 660 |

| 1100 | 44 | 1118 | 1676 | 1118 | 695 |

| 1150 | 46 | 1168 | 1753 | 1168 | 727 |

| 1200 | 48 | 1220 | 1829 | 1220 | 759 |

| 1300 | 52 | 1321 | 1981 | 1321 | 821 |

| 1400 | 56 | 1422 | 2134 | 1422 | 883 |

| 1500 | 60 | 1524 | 2286 | 1524 | 947 |

| 1600 | 64 | 1626 | 2438 | 1626 | 1010 |

| 1700 | 68 | 1727 | 2591 | 1727 | 1073 |

| 1800 | 72 | 1829 | 2743 | 1829 | 1137 |

| 1900 | 76 | 1930 | 2896 | 1930 | 1199 |

| 2000 | 80 | 2032 | 3048 | 2032 | 1263 |

8″ Equal Tee ASTM A860 WPHY 65

8" SCH XXS EQUAL TEE SEAMLESS BW ASTM A860 WPHY 65 ASME B16.9

USD190 USD185

SS 316 Concentric Reducer

SS 316 Concentric Reducer 8" x 6" Sch 40S Seamless BW ASME B16.9

USD98 USD96

Stainless Steel Long Radius Elbow

8” Sch10S Long Radius Elbow 90 Degree BW Stainless Steel 316L ASME B16.9

USD115 USD110

Galvanized 90 Degree Elbow

Galvanized 1 Inch BSPP 3000# 90 Degree Elbow ASTM A694 F52 ASME B16.11

USD6 USD5

8 Inch Pipe Cap A403 WP304

8 Inch Steel Pipe Cap Sch40S Seamless BW ASTM A403 WP304 ASME B16.9

USD37 USD36