- Home

- Blog Custom Layout

- Stainless Steel Pipe Fittings

- Stainless Steel Buttweld Fittings

Stainless Steel Buttweld Fittings

USD17 USD16

EQUAL TEE 2" SCH40S BW ASTM A403 WP316 ASME B16.9

- General Details

- Technical Info

- Tolerance

- Video

- Documents

- Related Products

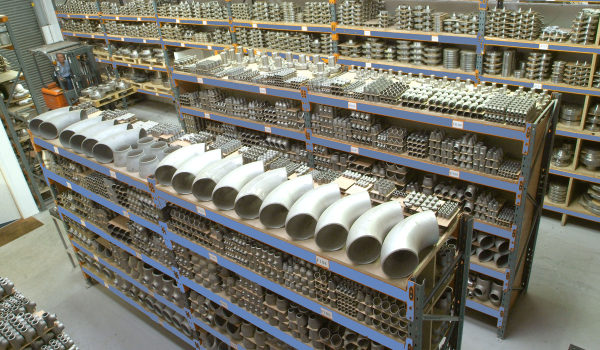

Zizi is a manufacturer of 304 & 316 Stainless Steel Buttweld Fittings which cover Equal & Reducing Tee, Pipe Elbow & Bend, Concentric & Eccentric Reducer.

With excellent performance, customers demanded stainless steel pipe fittings in various industries. We stock plenty of SS 304, SS 316 butt weld fittings in regular sizes, keep abreast of the schedule of ship, that’s why we always deliver the goods to you in time.

Stainless Steel Buttweld Fittings Exporters

Stainless Steel Buttweld Fittings Dimensions

| Standard | ASME B16.9 & ANSI B16.19 |

|---|---|

| Dimension | 1/2 to 80 Inch / DN15 — DN2000 |

| Thickness | Sch 10S, 20, STD, 40S, 80S, 100, 120,140, 160, XXS |

| Form | Seamless and Welded Pipe Fittings |

| End Preparation | BE (Beveled End) & PE ( Plain End) |

ASME B16. 9 Standard

It is the most common used specification standard for Factory-Made Wrought Buttwelding Fittings. It covers the requirements for dimensions, tolerances, ratings, testings and markings.

Buttwelding Fittings Catalogue

- To Change Directions

Butt Weld Elbows are used to connect two pipes with same or different nominal diameters, and to make the pipe turn to a certain direction of 45 degree or 90 degree.

Types: 90 Degree Elbow, 45 Degree Elbow, 180 Degree Elbow. Stainless Steel Pipe Bend

- To Provide Branches

Butt Weld Tees are used to join three different pipes forming a junction. It is normally called as “3-way fitting”. It symbolizes an alphabet “T” which include two inlets and single outlet.

There are two types that Equal Tee and Reducing Tee.

- To Block Pipeline

Butt Weld Caps are used to weld and block end of pipeline. We call it as Pipe Cap and End Cap.

- To Reduce Pipe Dimensions

Butt Weld Reducers are connected with pipes in different diameters.

Concentric Reducer, Eccentric Reducer, Reducing Elbow

- To Use With Flanges

Lap Joint Stub Ends are used in combination with a lap joint flange to make flanged connections.

ASTM Stainless Steel Grades

| Grades | ASTM A403 WP304/304L, WP304H, WP310S, WP316/316L, WP317, WP321, WP947 |

|---|---|

| UNS Code | S30400, S30403, S30409, S31008, S31600, S31603, S31700, S32100 |

Stainless Steel Pipe Fittings

Package of Stainless Steel Buttweld Fittings

We marked all Stainless Steel Buttweld Fittings with Grade, Lot No, Size, Standard and Schedule Thickness. The workers wrapped Stainless Steel Pipe Fittings with film individually. For the small diameter pipe fittings, we will pack them into wooden cases in the end, and use pallets to pack large diameter pipe fittings.

Package of Stainless Steel Pipe Fittings

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. Great care is taken during operation and transportation.

Inspection of Stainless Steel Equal Tee

Visual the surface of stainless steel equal tee fittings body.

Check the marking.<2″ SCH40S ASTM A403 WP316 ASME B16.9 ZZ155>

Measure dimensions. Such as outside diameter, height from end to end, wall thickness.

Buttweld Fittings vs Socket Weld Fittings

- Standard

ASME B16.9 for buttweld fittings

ASME B16.11 for socket weld fittings

- Dimensions

BW : 1/2″ to 48″

SW: 1/8″ to 4″

- Manufacturing

BW: Hot Forming

SW: Forging

- Price

Normally, the price of socket weld fittings is higher than butt weld fittings in similar size. But the extra cost of butt weld is higher for installation, considering labor cost and skilled welder.

316 Stainless Steel Properties

Chemical Composition,%

| C | Mn | P | S | Si | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 0.03 | 2.0 | 0.045 | 0.03 | 1.0 | 10-14 | 16-18 | 2-3 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 485(Mpa) | 170(Mpa) | 35(%) |

Tolerances for Butt Welding Fittings

| Nominal Diameter | O.D.For Bevel End | I.D.For End | Wall Thickness | Elbow | Tee | Reducer | Cap | 180°Elbow | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | B | C | M | H | E | O | K | Roughness | |||

| 15-65 | 1/2-2 1/2 | +1.6/-0.8 | ±0.8 | -12.50% | ±1.6 | ±1.6 | ±1.6 | ±1.6 | ±1.6 | ±3.2 | ±6.4 | ±6.4 | ±0.8 |

| 80-100 | 3-4 | ±1.6 | ±1.6 | ±6.4 | |||||||||

| 125-200 | 5-8 | +2.4/-1.6 | |||||||||||

| 250-450 | 10-18 | +4/-3.2 | ±3.2 | ±2.4 | ±2.4 | ±2.4 | ±2.4 | ±2.4 | ±9.6 | ||||

| 500-600 | 20-24 | +6.4/-4.8 | ±4.8 | ±3.2 | ±3.2 | ±3.2 | ±3.2 | ±4.8 | ±9.6 | ||||

| 650-750 | 26-30 | ||||||||||||

| ±4.8 | ±4.8 | ±4.8 | ±4.8 | ||||||||||

| 800-1200 | 32-48 | ||||||||||||

| 1250-1500 | 50-60 | +9.6/-6.4 | ±6.4 | ±9.6 | ±9.6 | ±9.6 | ±9.6 | ±9.6 | |||||

| 1550-1750 | 62-70 | +12.7/-9.6 | ±9.6 | ±12.7 | ±12.7 | ||||||||

| 1800-2000 | 72-80 | +16/-12 | ±12 | ±16 | ±16 | ||||||||

8″ Equal Tee ASTM A860 WPHY 65

8" SCH XXS EQUAL TEE SEAMLESS BW ASTM A860 WPHY 65 ASME B16.9

USD190 USD185

Socket Weld Half Coupling

2 Inch Class 6000 Socket Weld Half Coupling ASTM A105 ASME B16.11

USD12 USD11

Threaded Hex Head Bushing

Threaded Hex Head Bushing 3/8″×1/4″ BSPT ASTM A105 ASME B16.11

USD0.7 USD0.6

8 Inch Pipe Cap A403 WP304

8 Inch Steel Pipe Cap Sch40S Seamless BW ASTM A403 WP304 ASME B16.9

USD37 USD36