- Home

- Blog Custom Layout

- Steel Pipe Elbows

- Galvanized 90 Degree Elbow

Galvanized 90 Degree Elbow

USD6 USD5

Galvanized 1 Inch BSPP 3000# 90 Degree Elbow ASTM A694 F52 ASME B16.11

- General Details

- Technical Info

- DWG & SPEC

- Documents

- Related Products

Galvanized BSP Fittings

90 Degree Threaded Elbow Fittings in Class 3000 is usually taken surface treatment by zinc galvanized because it is cheaper, pretty and good to the thread.

Hot sale 90 degree elbow in carbon steel ASTM A105, A350, A694, offered in best quality and price without quantity and dimension restriction.

Carbon Steel Elbow is an essential and necessary fitting that design to change the direction of pipelines. Threaded Elbow is easy usage and leak proof so that it is very common in small diameter pipe systems. With galvanized surface, A694 F52 BSP Fittings have better corrosion resistance and the price obvious cost-effective. Our products are fully certified and 100% durable.

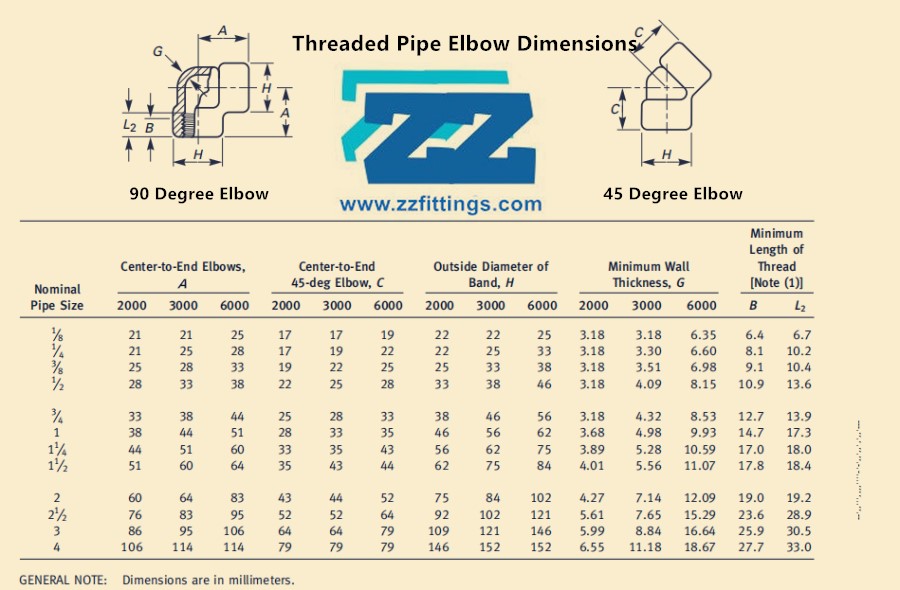

Threaded Pipe Elbow Dimensions

Threaded Pipe Elbow Dimensions

Standard: ASME/ANSI B16.11, BS3799

Size: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″

Pressure Ratings: 2000LB, 3000 LB, 6000 LB

Surface: Anti-rust Oil or Galvanized Elbow

Form: Straight and Reducing Elbow, 90 Degree Elbow and 45 Degree Elbow

Type: Socket Weld Elbow and Threaded Elbow

90 Degree Elbow Weight

This weight chart covers 90 degree threaded elbow in Class 2000lb, 3000lb and 6000lb.

| DN | NPS | 2000# | 3000# | 6000# |

| 6 | 1/8 | 0.08 | 0.1 | 0.18 |

| 8 | 1/4 | 0.08 | 0.15 | 0.3 |

| 10 | 3/8 | 0.13 | 0.3 | 0.45 |

| 15 | 1/2 | 0.22 | 0.45 | 0.72 |

| 20 | 3/4 | 0.32 | 0.7 | 1.2 |

| 25 | 1 | 0.5 | 1.2 | 1.65 |

| 32 | 1 1/4 | 0.8 | 1.5 | 2.7 |

| 40 | 1 1/2 | 0.9 | 2.6 | 3.3 |

| 50 | 2 | 1.6 | 3 | 6.05 |

| 65 | 2 1/2 | 3 | 5.8 | 9.9 |

| 80 | 3 | 5.6 | 8.9 | 16.4 |

| 100 | 4 | 10.5 | 13.5 | 23.5 |

Material & Grades of BSP 90 Degree Elbow

Stainless Steel: ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321

Carbon Steel: ASTM A105, A350 LF2, LF3, A694 F52, F60, F65, F70

Alloy Steel: ASTM A182 F1, F5, F9, F11, F12, F22, F91

Duplex Steel: ASTM A182 F51, F53, F55, S 31803, S 32205, S 32550, S 32750, S 32760

Features of Galvanized Elbow

- More durable

- Fine surface with cold galvanizing

- Rough surface with hot galvanizing

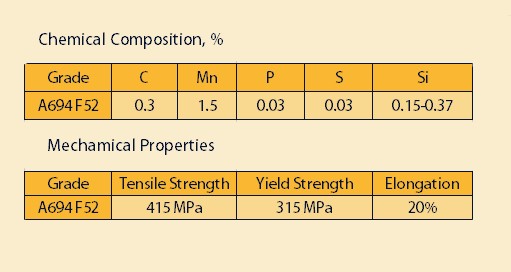

ASTM A694 F52 Material

- High strength due to the carbon content

- Good ductile, easy to form into different shapes

- Anti-abrasion

1 Inch Galvanized 90 Degree Elbow

Package

We marked all Carbon Steel Forged Fittings with Grade, Lot No, Size, Standard and Pressure. Our workers sleeved 1 Inch 90 Degree Elbow Galvanized into plastic bag individually, wrapped them with water-proof material, bundled packages with nylon rope.

1 Inch 90 Degree Elbow Package

Inspection

Visual the surface of 90 degree elbow body.

Check the marking. “1 BSPP 3000# 90D A694 F52 B16.11 168”

Measure dimensions. Such as outside diameter, wall thickness, height and thread length.

Test thread of threaded 90 degree elbow with Go-No Go Gauge.

What is Galvanizing ?

Galvanizing is one of the most widely used to methods for protecting metal from corrosion. It involves applying a thin coating of zinc to a thicker base metal, helping to shield it from the surrounding environment.

ASTM A694 F52 MATERIAL

ASTM A694 F52 Material

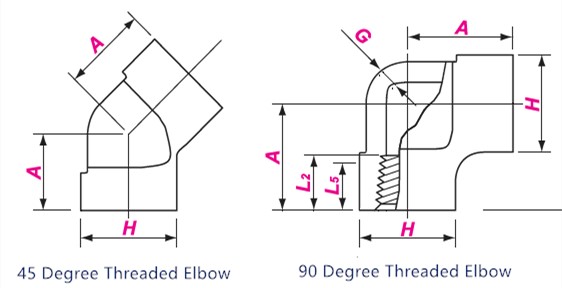

Specification & Drawing for Galvanized Threaded Elbow

Threaded Elbow Drawing & Dimensions

| Nominal Size | Center-to-End | Outside Diameter of Band | Wall Thickness | Length of Thread | ||||||||||||||

| DN | NPS |

|

45 Elbows A | H | G min | L 5 min | L 2 min | |||||||||||

| 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | |||||||

| 6 | 1/8 | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 | |||

| 8 | 1/4 | 21 | 25 | 28 | 17 | 19 | 22 | 22 | 25 | 33 | 3.18 | 3.3 | 6.6 | 8.1 | 10.2 | |||

| 10 | 3/8 | 25 | 28 | 33 | 19 | 22 | 25 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 | |||

| 15 | 1/2 | 28 | 33 | 38 | 22 | 25 | 28 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 | |||

| 20 | 3/4 | 33 | 38 | 44 | 25 | 28 | 33 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 | |||

| 25 | 1 | 38 | 44 | 51 | 28 | 33 | 35 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 | |||

| 32 | 1 1/4 | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17 | 18 | |||

| 40 | 1 1/2 | 51 | 60 | 64 | 35 | 43 | 44 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 | |||

| 50 | 2 | 60 | 64 | 83 | 43 | 44 | 52 | 75 | 84 | 102 | 4.27 | 7.14 | 12.09 | 19 | 19.2 | |||

| 65 | 2 1/2 | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 | |||

| 80 | 3 | 86 | 95 | 106 | 64 | 64 | 79 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 | |||

| 100 | 4 | 106 | 114 | 114 | 79 | 79 | 79 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33 | |||

Stainless Steel Eccentric Reducer

4"×3" Sch40S Stainless Steel Eccentric Reducer ASTM A403 WP304 ASME B16.9

USD15 USD13

A815 UNS S31803 Elbow Fittings

12" ELBOW 90 DEGREE LR SMLS ASME B16.9 ASTM A815 UNS S31803 SCH60

USD1516 USD1488

A182 F316 Threaded Coupling

Full Coupling Threaded 3000 LB BSPP 1 1/2" ASTM A182 F316 ASME B16.11

USD37 USD35