- Home

- Blog Custom Layout

- Socket Weld Fittings

- Class 3000 Socket Weld Fittings

Class 3000 Socket Weld Fittings

USD16 USD15

Socket Weld Fittings 1" Class 3000 Elbow ASTM A182 F316 ASME B16.11

- General Details

- Technical Info

- Specification

- Documents

- Related Products

Class 3000 Socket Weld Fittings are covering Stainless Steel 90 Degree Elbow, Straight & Reducing Tee, Cross, Steel Pipe Coupling, Cap, Union & Lateral.

They are produced to as standard of BS3799 and ANSI B16.11 and used only in conjunction with ANSI Pipe and are available in the same size range.

The ASME B16.11 fittings are most commonly used in industrial applications. The ASME has been responsible for producing pipe safety equipment. The standard is followed worldwide. This covers the aspects of the ratings, dimensions, tolerances, marking, and material requirements for socket-welding and threaded, hence all the forged fittings.

What is Difference between Socket Weld and Butt Weld Fittings?

Socket Weld Fittings VS Butt Weld Fittings

- Size

NPS 1/8 to 4 ( Socket Weld) and NPS 1/2 to 48 ( Butt Weld)

- Thickness

Class 3000, 6000, 9000 ( Socket Weld Fittings) and Schedule 10S, 20, STD, 40, 80, XS, 160, XXS ( Butt Weld)

- Surface

Anti rust oil for Socket Weld Fittings / Blasting & Painting for Butt Weld Fittings.

- Connection

Socket weld means a pipe is inserted into the body of fittings and then welding.

Butt weld means beveling end of pipe and fittings, then welding together.

- Cost

The price of socket weld fittings is higher than butt weld fittings in same size, but easier to install.

What is Tolerance for ASME Socket Weld Fittings?

Dimensions and tolerances shown are as specified in ASME/ANSI B16.11-1991. These agree substantially with BS3799:1974.

This ASME standard covers socket-welding and threaded forged fittings. However, These pipe fittings are characterized as Class 2000, 3000, and 6000 for threaded end fittings and Class 3000, 6000, and 9000 for socket-weld end fittings respectively.

| Nominal Diameter | All Fittings | 90° 45° Elbow Tee Cross Lateral | Coupling | Half Coupling Reducing insert | Union (Socket and Thread) | |||

| Socket Bore | Water Way Bore | Center To Bottom of Socket | Laying Lengths | Laying Lengths | Length Assem Nominal | |||

| DN | NPS | d1 | d2 | A H | E | F | L | |

| 6-8 | 1/8-1/4 | – | – | ±0.8 | ±1.5 | ±0.8 | ±1.5 | |

| 10-20 | 3/8-3/4 | +0.3/0 | ±0.4 | ±1.5 | ±3 | ±1.5 | ±1.5 | |

| 25-50 | 1-2 | – | – | ±2 | ±4 | ±2 | ±1.5 | |

| 65-100 | 2 1/2-4 | +0.4/0 | ±0.8 | ±2.5 | ±5 | ±2.5 | ±1.5 | |

Material & Grades of Forged Steel Fittings

Stainless Steel Socket Weld Fittings

ASTM A182 F304/304L/304H, F316/316L, F310, F317, F321, F309, F347, F904L

ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3

Duplex Steel 90 Degree Elbow

ASTM A182 F51, F53, F55, S 31803, 32205, 32550, 32750, 32760

Nickel Alloy Class 3000 Pipe Fittings

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 06600 (INCONEL 600 ) , UNS 06601 (INCONEL 601) , UNS 06625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

Cooper Alloy Steel Socket Weld Fittings

ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS C 70600 ( CU -NI- 45/10) , C 71500 ( CU -NI- 70/30)

Alloy Steel Forged Pipe Fittings

ASTM A182 F1, F5, F9, F11, F12, F22, F91

How Do We Pack & Mark Socket Weld Fittings?

Packing

Lining up all 3000 lb pipe fittings in cartons after surfaced anti-rust oil.

Sticking packing list on the outside of cartons.

Putting cartons into wooden case and bundle it.

Marking

Each socket weld fittings shall be permanently marked with the required identification by raised lettering or stamping. Which includes the type, size, pressure, material, grade and heat number.

ASTM A182 F316 SPECIFICATION

Chemical Composition

| GRADE | C | MN | SI | P | S | CR | MO | NI | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 316 | Min | – | – | – | 0 | – | 16 | 2 | 10 | – |

| Max | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | 0.1 | |

| 316L | Min | – | – | – | – | – | 16 | 2 | 10 | – |

| Max | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | 0.1 | |

| 316H | Min | 0.04 | 0.04 | 0 | – | – | 16 | 2 | 10 | – |

| max | 0.1 | 0.1 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | – |

Mechanical Properties

| GRADE | TENSILE STRENGTH | YIELD STRENGTH | ELONGATION | HARDNESS | |

|---|---|---|---|---|---|

| (MPA) MIN | (MPA) MIN | (% IN 50MM) MIN | (HR B) MAX | (HB) MAX | |

| 316 | 515 | 205 | 40 | 95 | 217 |

| 316L | 485 | 170 | 40 | 95 | 217 |

| 316H | 515 | 205 | 40 | 95 | 217 |

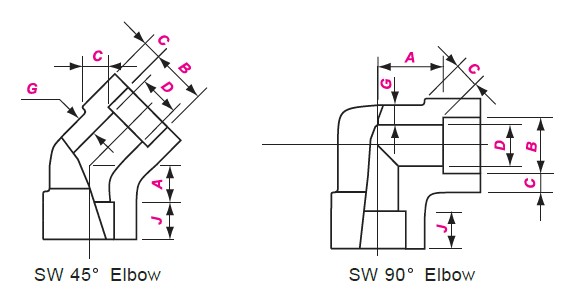

Socket Weld Elbow Drawing

| Nominal Size | Socket Bore Dia | Bore Dia of Fittings | Socket Wall Thickness | Body Wall | Depth of Socket | Center to Bottom of Socket | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | B | D | C | G | J | A | ||||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 90°Elbow Tee Cross | 45°Elbow | |||||||||||

| ave | min | ave | min | ave | min | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | – | 3.18 | 3.18 | 3.96 | 3.43 | – | – | 2.41 | 3.15 | – | 9.5 | 11 | 11 | – | 8 | 8 | – |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | – | 3.78 | 3.3 | 4.6 | 4.01 | – | – | 3.02 | 3.68 | – | 9.5 | 11 | 13.5 | – | 8 | 8 | – |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | – | 4.01 | 3.5 | 5.03 | 4.37 | – | – | 3.2 | 4.01 | – | 9.5 | 13.5 | 15.5 | – | 8 | 11 | – |

| 15 | 1/2 | 21.9 | 15 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19 | 25.5 | 11 | 12.5 | 15.5 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19 | 22.5 | 28.5 | 13 | 14 | 19 |

| 25 | 1 | 34 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27 | 32 | 14 | 17.5 | 20.5 |

| 32 | 1 1/4 | 42.8 | 34.3 | 28.7 | 22 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 | 27 | 32 | 35 | 17.5 | 20.5 | 22.5 |

| 40 | 1 1/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32 | 38 | 38 | 20.5 | 25.5 | 25.5 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 | 38 | 41 | 54 | 25.5 | 28.5 | 28.5 |

| 65 | 2 1/2 | 73.9 | 61.2 | – | – | 8.76 | 7.62 | – | – | – | – | 7.01 | – | – | 16 | 41 | – | – | 28.5 | – | – |

| 80 | 3 | 89.9 | 76.4 | – | – | 9.52 | 8.3 | – | – | – | – | 7.62 | – | – | 16 | 57 | – | – | 32 | – | – |

| 100 | 4 | 115.5 | 100.7 | – | – | 10.69 | 9.35 | – | – | – | – | 8.56 | – | – | 19 | 66.5 | – | – | 41 | – | – |

Full Coupling 3000

2 Inch Class 3000 Socket Weld Full Coupling ASTM A182 F11 ASME B16.11

USD22 USD20

Stainless Steel Bushings

3/4 x 1/2 NPT Stainless Steel 304L Flush Bushing Reducer ASME B16.11

USD6 USD5

45 Degree Long Radius Elbow

6” STD 45 Degree Long Radius Elbow Seamless ASTM A420 WPL6 ASME B16.9

USD8 USD7

Socket Weld Half Coupling

2 Inch Class 6000 Socket Weld Half Coupling ASTM A105 ASME B16.11

USD12 USD11