- Home

- Blog Custom Layout

- Steel Pipe Unions

- Stainless Steel Union

Stainless Steel Union

USD6 USD5

Stainless Steel Socket Weld Union 1 inch ASTM A182 F316 ASME B16.11

- General Details

- Technical Info

- SW SPEC

- THD SPEC

- Documents

- Related Products

Quality stainless steel forged fittings manufacturer and exporter supplies 1 inch pipe union ASTM A182 F316 ASME B16.11 in socket weld and thread types.

We offer the complete range of forged fittings including socket weld fittings and threaded fittings. Like Elbows, Tees, Crosses, Couplings, Caps, Hexagonal Nipple, Threaded Plugs, Union and Lateral. These pipe fittings are fabricated by best original material which buy from famous and big steel mill.

Forged Fittings Specification

Standard: ASME B16.11, SH3410, JIS B2316, BS3799

Size: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″

Pressure: 3000LB, 6000LB, 9000LB

Types: Socket Weld Fittings and Threaded Pipe Fittings

Carbon Steel Grades

ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3

Stainless Steel Grades

ASTM A182 F304/304L/F304H, F316/316L, F310, F317, F321, F309

Duplex Steel Grades

ASTM A182 F51, F53, F55, F56, F57

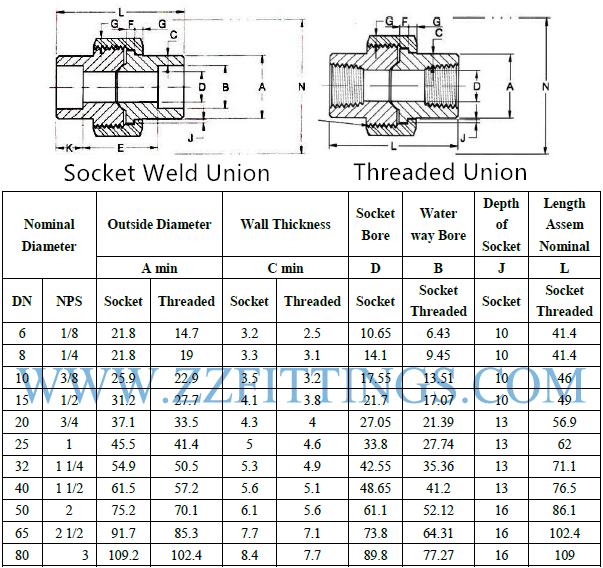

Stainless Steel Union Dimensions

Steel Pipe Union Dimensions

Weight Chart of Steel Pipe Union

The unions are available in small dimensions which below 3 inch so that the weight is light. So we can send them by courier or air, the weight can be used to check freight. The weight chart can be used in socket weld and threaded union.

| Nominal Size | Approx. Weight/kg | |

| DN | NPS | Class 3000 |

| 6 | 1/8 | 0.06 |

| 8 | 1/4 | 0.06 |

| 10 | 3/8 | 0.08 |

| 15 | 1/2 | 0.14 |

| 20 | 3/4 | 0.2 |

| 25 | 1 | 0.28 |

| 32 | 1 1/4 | 0.48 |

| 40 | 1 1/2 | 0.52 |

| 50 | 2 | 1 |

| 65 | 2 1/2 | 1.6 |

| 80 | 3 | 1.8 |

Quality Assurance of Class 3000 Pipe Fittings

Forged steel fittings and flanges are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. After the processing down, we will do below inspection.

Visually examined surface and marking.

Measure the size and thickness.

Test the properties of stainless steel.

Package of Stainless Steel Threaded Union

- Putting them into small plastic bags.

- Lining up threaded unions in cartons.

- Packing cartons in wooden cases.

- Sticking shipping mark on outside of packages.

Certificates for Forged Steel Fittings and Flanges

ISO 9001 certificate

CE certificate

EN10204 B3.1 MTC

Third party inspection report

ABS, BV, DNV and API

316 Stainless Steel Properties

Chemical Composition

| C | Mn | Si | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0.035 | 2 | 0.75 | 0.045 | 0.03 | 16-18 | 2-3 | 10-14 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 515 (Mpa) | 205 (Mpa) | 40 (%) |

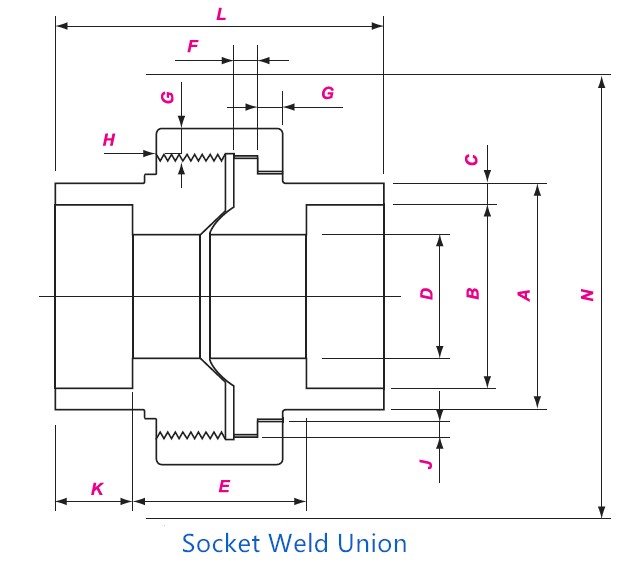

Drawings & Specification for Socket Weld Union

Socket Weld Union Drawing

| Nominal Size | Pipe End | Socket Bore Dia | Socket Wall | Water Way Bore | Laying Length | Male Flange | Nut | THRD Per lnch | Bearing | Depth of Cocket | Length Assem | Clear Assem Nut | |

| DN | NPS | A | B | C | D | E | F | G | H | J | K | L | N |

| 6 | 1/8 | 21.8 | 10.9 | 3.2 | 6.1 | 20.7 | 3.2 | 3.2 | 16 | 1.2 | 9.7 | 41.4 | 51 |

| 8 | 1/4 | 21.8 | 14.3 | 3.3 | 8.5 | 20.7 | 3.2 | 3.2 | 16 | 1.2 | 9.7 | 41.4 | 51 |

| 10 | 3/8 | 25.9 | 17.7 | 3.5 | 11.8 | 23.8 | 3.4 | 3.4 | 14 | 1.4 | 9.7 | 46 | 56 |

| 15 | 1/2 | 31.2 | 21.9 | 4.1 | 15 | 23.8 | 3.7 | 3.7 | 14 | 1.5 | 9.7 | 49 | 59 |

| 20 | 3/4 | 37.1 | 27.3 | 4.3 | 20.2 | 28.6 | 4.1 | 4.1 | 11 | 1.7 | 12.7 | 56.9 | 66 |

| 25 | 1 | 45.5 | 34 | 5 | 25.9 | 30.2 | 4.6 | 4.4 | 11 | 1.9 | 12.7 | 62 | 79 |

| 32 | 1 1/4 | 54.9 | 42.8 | 5.3 | 34.3 | 36.6 | 5.3 | 5.2 | 10 | 2.1 | 12.7 | 71.1 | 94 |

| 40 | 1 1/2 | 61.5 | 48.9 | 5.5 | 40.1 | 38.1 | 5.8 | 5.6 | 10 | 2.3 | 12.7 | 76.5 | 112 |

| 50 | 2 | 75.2 | 61.2 | 6 | 51.7 | 41.4 | 6.6 | 6.4 | 10 | 2.7 | 15.7 | 86.1 | 132 |

| 65 | 2 1/2 | 91.7 | 73.9 | 7.7 | 61.2 | 56.9 | 7.5 | 7.1 | 8 | 3.1 | 15.7 | 102.4 | 150 |

| 80 | 3 | 109.2 | 89.9 | 8.3 | 76.4 | 58.7 | 8.3 | 8 | 8 | 3.5 | 15.7 | 109 | 176 |

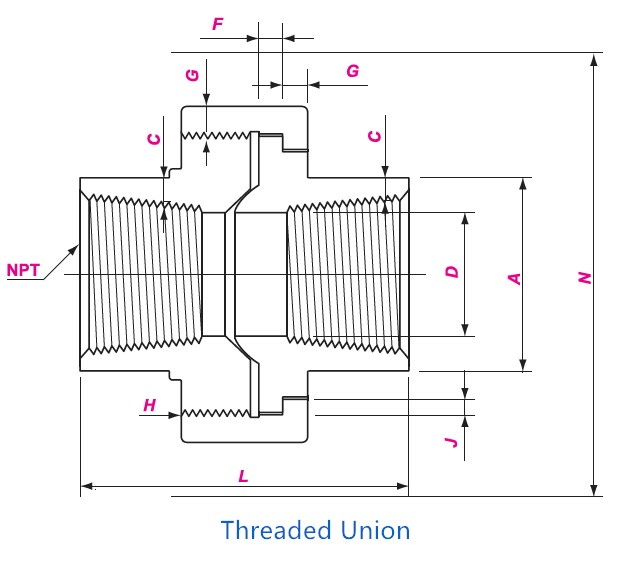

Drawing & Specification for Threaded Union

Threaded Union Drawing

| Nominal Size | Pipe End | Wall | Bore | Male Flange | Nut | THRD Per Inch | Bearing | Length Assem | Clear Assem.Nut | |

| DN | NPS | Amin | Cmin | D | Fmin | Gmin | H | Jmin | Lnom | N |

| 6 | 1/8 | 14.7 | 2.4 | 8.4 6.4 |

3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 8 | 1/4 | 19.1 | 3.0 | 11.1 9.4 |

3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 10 | 3/8 | 22.9 | 3.2 | 14.3 13.5 |

3.4 | 3.4 | 14 | 1.4 | 46.0 | 56 |

| 15 | 1/2 | 27.7 | 3.7 | 17.9 17.1 |

3.7 | 3.7 | 14 | 1.5 | 49.0 | 59 |

| 20 | 3/4 | 33.5 | 3.9 | 23.0 21.4 |

4.1 | 4.1 | 11 | 1.7 | 56.9 | 66 |

| 25 | 1 | 41.4 | 4.5 | 29.0 27.7 |

4.6 | 4.4 | 11 | 1.9 | 62.0 | 79 |

| 32 | 1 1/4 | 50.5 | 4.9 | 37.7 35.4 |

5.3 | 5.2 | 10 | 2.1 | 71.1 | 94 |

| 40 | 1 1/2 | 57.2 | 5.1 | 43.5 41.2 |

5.8 | 5.6 | 10 | 2.3 | 76.5 | 112 |

| 50 | 2 | 70.1 | 5.5 | 55.6 52.1 |

6.6 | 6.4 | 10 | 2.7 | 86.1 | 132 |

| 65 | 2 1/2 | 85.3 | 7.0 | 66.3 64.3 |

7.5 | 7.1 | 8 | 3.1 | 102.4 | 150 |

| 80 | 3 | 102.4 | 7.6 | 82.6 77.3 |

8.3 | 8.0 | 8 | 3.5 | 109.0 | 176 |

Socket Weld Half Coupling

2 Inch Class 6000 Socket Weld Half Coupling ASTM A105 ASME B16.11

USD12 USD11