- Home

- Blog Custom Layout

- Steel Pipe Tees

- Alloy Steel Tee Equal

Alloy Steel Tee Equal

USD160 USD155

Equal Tee 10 inch PN9.8 BW ASTM A234 WP12 ASME B16.9

- General Details

- Technical Info

- DWG & SPEC

- Documents

- Related Products

Alloy steel tee fittings have a good strength and corrosion resistance, which providing T branch to change the direction of flow in the piping system.

As a proved manufacturer of alloy steel pipe fittings and forged steel flanges by ISO, CE, ABS, BV, DNV, TUV. The quality is totally in control. Whatever small or large quantity, they are welcomed and supplied in short time.

We produce the alloy steel butt weld pipe fittings both in seamless and weld types, it depends on the sizes or customer’s requirements.

Alloy Steel Straight Tee Specification

Standard: ASME B16.9, SH3408, HG/T21635, HG/T21631, SY/T0510

Size: NPS 1/2 to 48 / DN15 to DN1200

Thickness: Sch 10S, 20, STD, 40, XS, 160, XXS

Grades: ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Surface: Blasting and Painting.

Package: Non Fumigation Wooden Cases.

What is Tolerance for Butt Weld Tee?

Tolerance is the allowable variation for any given size in order to achieve a proper function. It lists lower and upper limit dimensions of butt weld equal tee.

| Nominal Diameter | O.D For Bevel End | I.D For End | Wall Thickness | Tee | |||

| DN | NPS | C | M | ||||

| 15-65 | 1/2-2 1/2 | +1.6/-0.8 | ±0.8 | -12.50% | ±1.6 | ±1.6 | |

| 80-100 | 3-4 | ±1.6 | ±1.6 | ||||

| 125-200 | 5-8 | +2.4/-1.6 | |||||

| 250-450 | 10-18 | +4/-3.2 | ±3.2 | ±2.4 | ±2.4 | ||

| 500-600 | 20-24 | +6.4/-4.8 | ±4.8 | ±3.2 | ±3.2 | ||

| 650-750 | 26-30 | ||||||

| ±4.8 | ±4.8 | ||||||

| 800-1200 | 32-48 | ||||||

| 1250-1500 | 50-60 | +9.6/-6.4 | ±6.4 | ±9.6 | ±9.6 | ||

| 1550-1750 | 62-70 | +12.7/-9.6 | ±9.6 | ||||

Alloy Steel Tee Types

- Shape

Straight and Reducing Tee

- Connection

Butt Weld, Socket Weld and Threaded Pipe Tee

Package of 10 inch Equal Tee

Blasting and Painting.

Marking ” Equal Tee 10″ PN9.8 ASTM A234 WP12 ZZ188″

Packing into wooden cases.

Sticking shipping mark on the wooden case.

Package 10 Inch Alloy Steel Tee

Alloy Steel Tee Weight Calculation Formula

Computational Formula : 0.02466 x (S+1.5) x <D-(S+1.5)> x (3C-D/2) / 1000

- S = Thickness

- D = Outside Diameter

- C = Run Length

All units of sizes are mm.

Weight Chart of Straight Tee

Comparing with the weight formula, the chart of straight tee is more easy to get the weights

| DN | NPS | STD | 40 | XS | 80 | 160 | XXS |

| 15 | 1/2 | 0.2 | 0.2 | 0.21 | 0.21 | ||

| 20 | 3/4 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| 25 | 1 | 0.3 | 0.3 | 0.5 | 0.5 | ||

| 32 | 1 1/4 | 0.6 | 0.6 | 0.7 | 0.7 | ||

| 40 | 1 1/2 | 0.9 | 0.9 | 1.3 | 1.3 | 1.5 | 1.3 |

| 50 | 2 | 1.5 | 1.5 | 2.2 | 2.2 | 2.7 | 3.4 |

| 65 | 2 1/2 | 2.7 | 2.7 | 3 | 3 | 3.1 | 3.8 |

| 80 | 3 | 3.8 | 3.8 | 4.3 | 4.3 | 5.5 | 6.1 |

| 90 | 3 1/2 | 4.6 | 4.6 | 6 | 6 | ||

| 100 | 4 | 6.5 | 6.5 | 7.7 | 7.7 | 10.2 | 12.9 |

| 125 | 5 | 9.7 | 9.7 | 13.5 | 13.5 | 19.8 | 25.7 |

| 150 | 6 | 14 | 14 | 19.3 | 19.3 | 34 | 30.6 |

| 200 | 8 | 24.5 | 24.5 | 34.5 | 34.5 | 50 | 47.7 |

| 250 | 10 | 41.3 | 41.3 | 58.4 | 67.5 | 111 | 84.7 |

| 300 | 12 | 65 | 69 | 76.5 | 105 | 158 | 129 |

| 350 | 14 | 83 | 96 | 104 | 142 | 232 | |

| 400 | 16 | 110 | 120 | 120 | 187 | 335 | |

| 450 | 18 | 132 | 170 | 159 | 263 | 564 | |

| 500 | 20 | 168 | 240 | 192 | 356 | 756 | |

| 550 | 22 | 185 | 209 | 416 | 1002 | ||

| 600 | 24 | 222 | 345 | 251 | 548 | 1215 |

Features of Alloy Steel Pipe Fittings

- Harden-ability

- Corrosion resistance

- Strength

- Form-ability

- Weld-ability

- Ductility

Properties of Alloy Steel A234 Pipe Fittings

| Grade | C | Mn | Si | S | P | Cr | Mo |

|---|---|---|---|---|---|---|---|

| A234WP12 | 0.05-0.2 | ≤0.6 | ≤0.45 | ≤0.04 | ≤0.03 | 0.8-1.25 | 0.44-0.65 |

| A234WP5 | ≤0.15 | ≤0.6 | ≤0.5 | ≤0.04 | ≤0.03 | 4.0-6.0 | 0.44-0.65 |

| A234WP11 | 0.05-0.2 | 0.3-0.8 | 0.5-1 | ≤0.030 | ≤0.030 | 1-1.5 | 0.44-0.65 |

| A234WP22 | 0.05-0.15 | 0.3-0.6 | ≤0.5 | ≤0.04 | ≤0.04 | 2-2.5 | 0.87-1.13 |

| A234WP91 | 0.08-0.12 | 0.3-0.6 | 0.2-0.5 | ≤0.02 | ≤0.015 | 8-9.5 | 0.85-1.05 |

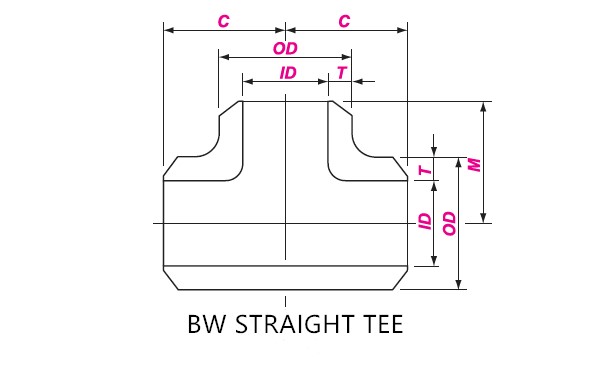

Drawing & Specification for Alloy Steel Equal Tee

BW STRAIGHT TEE DRAWING

| Nominal Size | Outside Diameter at Bevel | Center to End | ||

| DN | NPS | OD | C | M |

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 29 | 29 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 1 1/4 | 42.2 | 48 | 48 |

| 40 | 1 1/2 | 48.3 | 57 | 57 |

| 50 | 2 | 60.3 | 64 | 64 |

| 65 | 2 1/2 | 73 | 76 | 76 |

| 80 | 3 | 88.9 | 86 | 86 |

| 125 | 5 | 141.3 | 124 | 124 |

| 150 | 6 | 168.3 | 143 | 143 |

| 200 | 8 | 219.1 | 178 | 178 |

| 250 | 10 | 273 | 216 | 216 |

| 300 | 12 | 323.8 | 254 | 254 |

| 350 | 14 | 355.6 | 279 | 279 |

| 400 | 16 | 406.4 | 305 | 305 |

| 450 | 18 | 457 | 343 | 343 |

| 500 | 20 | 508 | 381 | 381 |

| 550 | 22 | 559 | 419 | 419 |

| 600 | 24 | 610 | 432 | 432 |

| 650 | 26 | 660 | 495 | 495 |

| 700 | 28 | 711 | 521 | 521 |

| 750 | 30 | 762 | 559 | 559 |

| 800 | 32 | 813 | 597 | 597 |

| 850 | 34 | 864 | 635 | 635 |

| 900 | 36 | 914 | 673 | 673 |

| 950 | 38 | 965 | 711 | 711 |

| 1000 | 40 | 1016 | 749 | 749 |

| 1050 | 42 | 1067 | 762 | 711 |

| 1100 | 44 | 1118 | 813 | 762 |

| 1150 | 46 | 1168 | 851 | 800 |

| 1200 | 48 | 1219 | 889 | 838 |

| 1300 | 52 | 1321 | 965 | 914 |

| 1400 | 56 | 1422 | 1041 | 965 |

| 1500 | 60 | 1524 | 1118 | 1016 |

| 1600 | 64 | 1626 | 1194 | 1092 |

| 1700 | 68 | 1727 | 1270 | 1168 |

| 1800 | 72 | 1829 | 1320 | 1245 |

| 1900 | 76 | 1930 | 1422 | 1320 |

| 2000 | 80 | 2032 | 1499 | 1397 |

Stainless Steel Equal Tee

6 Inch Sch 80S Equal Tee Stainless Steel ASTM A403 WP316 ASME B36.19

USD238 USD235

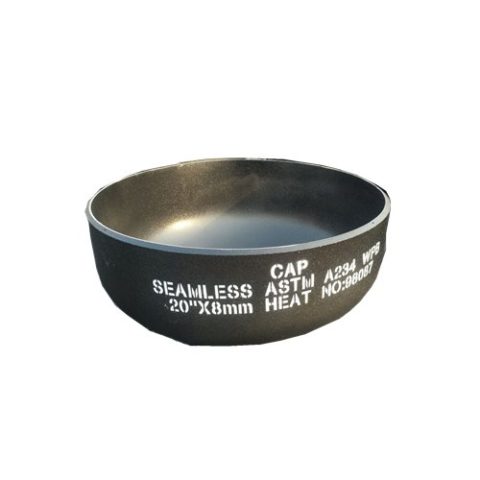

Large Diameter Steel Pipe Cap

Seamless Steel Pipe Cap BE 20" x 8mm BW ASTM A234 WPB ASME B16.9

USD50 USD48

Alloy Steel Forged Fittings

Elbow, Tee, Coupling, Cap, Plug, Bushing, Union, Nipple, Forged Steel Olets

USD500 USD350

ASTM A234 WPB Concentric Reducer

Concentric Reducer Seamless 3" x 2" Sch160 BW ASTM A234 GR WPB

USD9 USD8