- Home

- Blog Custom Layout

- Socket Weld Equal Tee

Socket Weld Equal Tee

USD12 USD11

DN25 PN20 Socket Weld Equal Tee Stainless Steel 304 SH/T3410

- General Details

- Technical Info

- DWG & SPEC

- Documents

- Related Products

Stainless steel socket weld equal tee can provide three branch in same size specification for inserting the pipes or fittings and then welding.

ISO certified quality manufacturer of socket weld pipe fittings that supplies DN25 PN20 Equal Tee SW Stainless Steel 304 SH/T3410 for Indonesia market.

We always offer high quality stainless steel pipe fittings in standard of ASME B16.11, BS3799 and SH/T3410 with best price. Also have specialization to manufacture customized equal tee as per customers’ specifications, whatever small or large quantity order, they are always welcomed.

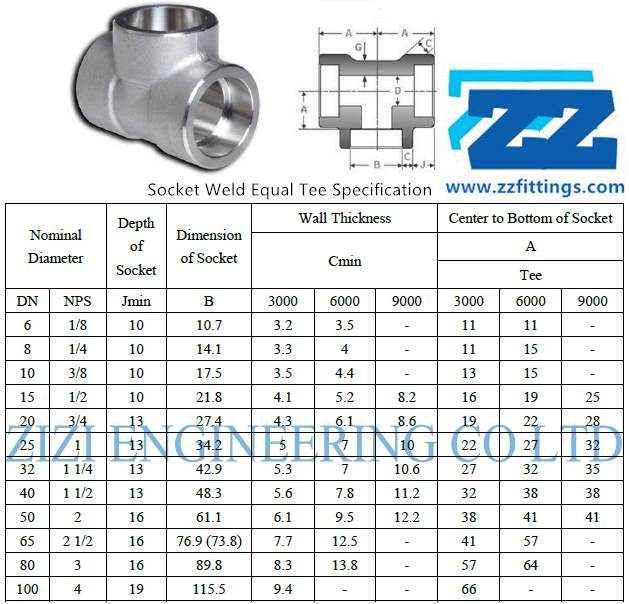

Socket Weld Equal Tee Specification

| Size | 1/8″, 1/4″, 3/8″, 1/2″, 1/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″ |

| Pressure | 3000LB, 6000LB, 9000LB |

| Standard | ASME B16.11, GB/T14383, SH3410, HG/T21634, JIS B2316, BS3799 |

| Surface | Anti-rust Oil |

| Package | Carton and Wooden Cases |

Socket Weld Equal Tee Specification

Alloy Steel Grades

ASTM A182 F1, F5, F9, F11, F12, F22, F91

Carbon Steel Grades

ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3

Stainless Steel Grades

ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321

Duplex Steel Grades

ASTM A182 F51, F53, F55, S 31803, 32205, 32550, 32750, 32760

Stainless Steel Forged Tee Weight

Forged steel pipe tee means socket weld and threaded tee. Now we list the weight for both of them as following.

| Nominal Size | Socket Weld Equal Tee | Threaded Equal Tee | |||||

| DN | NPS | 3000 | 6000 | 9000 | 2000 | 3000 | 6000 |

| 6 | 1/8 | 0.13 | 0.22 | / | 0.13 | 0.22 | 0.35 |

| 8 | 1/4 | 0.13 | 0.22 | / | 0.13 | 0.22 | 0.57 |

| 10 | 3/8 | 0.16 | 0.45 | / | 0.16 | 0.4 | 0.66 |

| 15 | 1/2 | 0.35 | 0.55 | 1.15 | 0.35 | 0.58 | 1.15 |

| 20 | 3/4 | 0.4 | 0.9 | 1.8 | 0.45 | 0.9 | 1.8 |

| 25 | 1 | 0.66 | 1.46 | 2.25 | 0.66 | 1.46 | 2.25 |

| 32 | 1 1/4 | 1 | 1.9 | 3.95 | 1 | 1.9 | 3.95 |

| 40 | 1 1/2 | 1.4 | 3.4 | 4.87 | 1.4 | 3.4 | 4.87 |

| 50 | 2 | 2.2 | 3.7 | 8.89 | 2.2 | 3.8 | 8.89 |

| 65 | 2 1/2 | 4 | 7.2 | / | 4.2 | 7.2 | 12.8 |

| 80 | 3 | 6.15 | 10.7 | / | 6.15 | 10.7 | 21.8 |

| 100 | 4 | 14.3 | / | / | 14.7 | 17.9 | 29.5 |

Differences Between Socket Weld and Butt Weld

When you are inserting one pipe into the pipe fittings, this creates the “socket”, and then welding them together. With this socket, ou have more material below the weld surface, making it a bit easier for your welders.

But for butt welding, your welders must be good at welding since butt weld is much more difficult. It means you joining two pipes end to end and then welding them together. There is no allowed for any error in a butt weld.

1 Inch Socket Weld Tee

Marking and Packing

Our workers are marking ” DN25 SW OD33.4 PN20 304 SH/T3410″ on stainless steel socket weld equal tee. Then sleeved 1″ Socket Weld Tee into plastic bag individually after done anti-rust oil. Finally put all of them into cartons and wooden cases.

Inspection

- Visual the surface of socket weld fittings. Such as dents, die marks, porosity.

- Check the marking. Such as size, grade, pressure, standard, heat No.

- Measure dimensions. Such as outside diameter, thickness, socket dimensions.

- Test the chemical composition of stainless steel 304 equal tee.

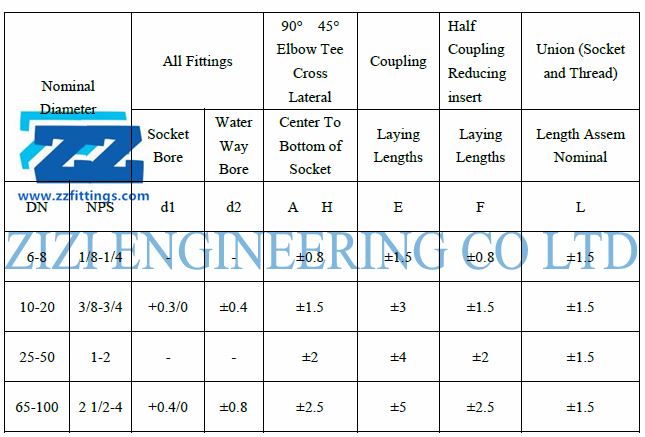

Tolerance for Socket Weld Fittings?

Tolerance for Socket Weld Fittings

Why Choose Us for ASME B16.11 Fittings?

ISO certified quality

Abundant stock

One stop service

Attractive price

Offer in time

Short delivery time

ASTM A182 F304 Properties

Chemical Properties

| C | Mn | Si | P | S | Cr | Ni |

| 0.03 | 2 | 0.75 | 0.045 | 0.03 | 18-20 | 8-10.5 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

| 515 (Mpa) | 205 (Mpa) | 40 (%) |

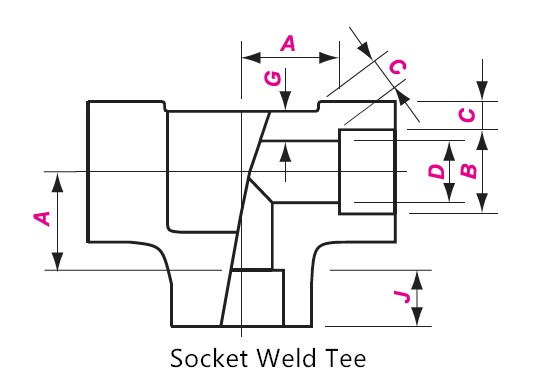

Drawing & Specification for Socket Weld Equal Tee

Drawing of Socket Weld Tee

| Nominal Size | Socket Bore Dia. | Bore Dia. of Fittings | Socket Wall Thickness | Body Wall | Depth of Socket | Center to Bottom of Socket | ||||||||||||

| D | C | Gmin | Jmin | A | ||||||||||||||

| DN | NPS | B | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 |

|

6000 | 9000 | ||||

| ave | min | ave | min | ave | min | |||||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | – | 3.18 | 3.18 | 3.96 | 3.43 | – | – | 2.41 | 3.15 | – | 9.5 | 11 | 11 | – |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | – | 3.78 | 3.3 | 4.6 | 4.01 | – | – | 3.02 | 3.68 | – | 9.5 | 11 | 13.5 | – |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | – | 4.01 | 3.5 | 5.03 | 4.37 | – | – | 3.2 | 4.01 | – | 9.5 | 13.5 | 15.5 | – |

| 15 | 1/2 | 21.9 | 15 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19 | 25.5 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19 | 22.5 | 28.5 |

| 25 | 1 | 34 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27 | 32 |

| 32 | 1 1/4 | 42.8 | 34.3 | 28.7 | 22 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 | 27 | 32 | 35 |

| 40 | 1 1/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32 | 38 | 38 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 | 38 | 41 | 54 |

| 65 | 2 1/2 | 73.9 | 61.2 | – | – | 8.76 | 7.62 | – | – | – | – | 7.01 | – | – | 16 | 41 | – | – |

| 80 | 3 | 89.9 | 76.4 | – | – | 9.52 | 8.3 | – | – | – | – | 7.62 | – | – | 16 | 57 | – | – |

| 100 | 4 | 115.5 | 100.7 | – | – | 10.69 | 9.35 | – | – | – | – | 8.56 | – | – | 19 | 66.5 | – | – |

Concentric Swage Nipple

2" x 1"Schedule 80 Concentric Swage Nipple TOE ASTM A182 F12 MSS SP-95

USD13 USD12

Stainless Steel Hex Nipple

1/2 inch Sch80 NPT Hex Nipple Stainless Steel 304 ASME B16.11

USD3 USD2.5

45 Degree Long Radius Elbow

6” STD 45 Degree Long Radius Elbow Seamless ASTM A420 WPL6 ASME B16.9

USD8 USD7

A815 UNS S31803 Elbow Fittings

12" ELBOW 90 DEGREE LR SMLS ASME B16.9 ASTM A815 UNS S31803 SCH60

USD1516 USD1488