- Home

- Blog Custom Layout

- Duplex Steel Pipe Fittings

- Socket Weld Coupling

Socket Weld Coupling

USD20 USD18

2" Class 3000 Socket Weld Coupling ASTM A182 F51 ASME B16.11

- General Details

- Technical Info

- DWG & SPEC

- Documents

- Related Products

Socket weld coupling is a combination of provision that can join two pipes or tubes together with a socket at one end or both ends.

Socket Weld Fittings also cover 90 degree elbow, 45 degree elbow, tee, cross, union, cap, lateral. Duplex stainless steel pipe fittings is our hot sale product, especially Class 3000 Stainless Steel Socket Weld Fittings in material grade 304 & 316.

They are used for their good mechanical properties in the as-cast (and therefore as-welded condition) and their excellent corrosion resistance properties (particularly to stress corrosion cracking).

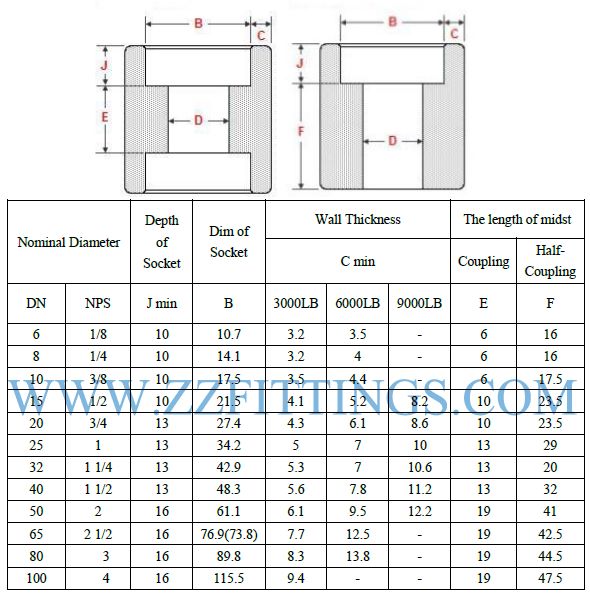

Socket Weld Coupling Dimensions

| Size | 1/8”, 1/4”, 3/8”, 1/2”, 3/4”, 1”, 1 1/4”, 1 1/2”, 2”, 2 1/2”, 3”, 4”, 6″ |

|---|---|

| Pressure | 3000LB and 6000LB |

| Standard | GB/T14626, ANSI B16.11, BS3799 |

| Form | Full Coupling and Half Coupling, Straight Coupling and Reducing Coupling |

Socket Weld Coupling Dimensions

Material & Grades for Full Coupling

ASTM A182 F304/304L/304H, F309S/309H, F310S, F316/316L, F317, F321, F347

Alloy Steel Full Coupling

ASTM A182 F1, F5, F9, F11, F12, F22, F91

Carbon Steel Forged Coupling

ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3

Duplex Steel Forged Coupling

ASTM A182 F51, F53, F55, F50, F57, F59, F60, F61

RFQ of Class 3000 Pipe Fittings

What is your package?

Cartons and Wooden Cases.

How to against rust during the shipment?

Surfaced anti-rust oil on the body of coupling before shipping.

B16.11 Full Coupling Weight Chart

The weight of coupling is available in both socket weld and threaded. The size is from NPS 1/8″ to 4″ and pressure ratings cover Class 3000# and 6000#. So we can call them as high pressure pipe fittings.

| Nominal Size | Threaded | Socket Weld | |||

| DN | NPS | 3000# | 6000# | 3000# | 6000# |

| 6 | 1/8 | 0.06 | 0.09 | 0.06 | 0.06 |

| 8 | 1/4 | 0.08 | 0.13 | 0.06 | 0.08 |

| 10 | 3/8 | 0.11 | 0.24 | 0.08 | 0.1 |

| 15 | 1/2 | 0.22 | 0.4 | 0.14 | 0.16 |

| 20 | 3/4 | 0.3 | 0.52 | 0.2 | 0.28 |

| 25 | 1 | 0.55 | 1.06 | 0.28 | 0.48 |

| 32 | 1 1/4 | 0.86 | 1.32 | 0.48 | 0.66 |

| 40 | 1 1/2 | 1.26 | 2.2 | 0.52 | 0.84 |

| 50 | 2 | 1.65 | 3.37 | 1 | 1.6 |

| 65 | 2 1/2 | 3 | 4.81 | 1.6 | 2.2 |

| 80 | 3 | 4.25 | 7.25 | 1.8 | 2.4 |

| 100 | 4 | 7.8 | 12 | 2.8 | – |

Inspection of Steel Pipe Coupling

- Visual the surface

- Measure the dimensions.

- Check the marking.

- Test the properties.

Export Country for Forged Steel Fittings

Asia: Vietnam, Singapore, India, Indonesia, Malaysia, Thailand, Kazakhstan

Africa: Nigeria, Madagascar,Ghana, Kenya, Angola, Mauritius, Uganda

Middle East: Saudi Arabia, Qatar, Israel, Egypt, Oman, Jordan

Latin America: Uruguay, Peru, Chile, Brasil, Ecuador, Colombia

Oceania: Papua New Guinea, Australia, New Zealand, Solomon

Europe: Greece, UK, Poland, Ukraine, France, Spain, Italy, Ukraine

ASTM A182 F51 VS F316

| Grade | C | Mn | Si | S | P | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| F51 | ≤0.03 | ≤2.0 | ≤1.0 | ≤0.02 | ≤0.03 | 21-23 | 0.08-0.2 | 4.5-6.5 |

| F316 | ≤0.035 | ≤2.0 | ≤0.75 | ≤0.03 | ≤0.045 | 16-18 | 2-3 | 14-16 |

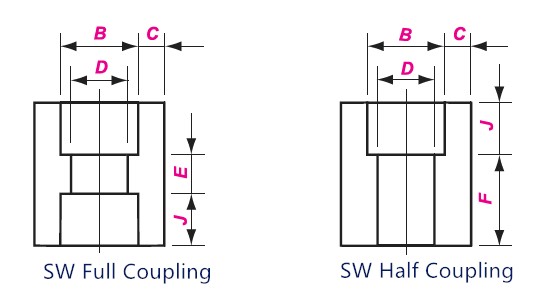

Drawing & Specification for Socket Weld Coupling

Socket Weld Coupling Drawing

| Nominal Size | Socket Bore Dia. | Bore Dia. of fittings | Socket Wall Thickness | Depth of Socket | Laying Lengths | Laying lengths | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | B | D | C | Jmin | E | F | |||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | |||||||||

| ave | min | ave | min | ave | min | |||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | / | 3.18 | 3.18 | 3.96 | 3.43 | / | / | 9.5 | 6.5 | 16.0 |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | / | 3.78 | 3.30 | 4.60 | 4.01 | / | / | 9.5 | 6.5 | 16.0 |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | / | 4.01 | 3.50 | 5.03 | 4.37 | / | / | 9.5 | 6.5 | 17.5 |

| 15 | 1/2 | 21.9 | 15.0 | 11.0 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 9.5 | 9.5 | 22.5 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 12.5 | 9.5 | 24.0 |

| 25 | 1 | 34.0 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 12.5 | 12.5 | 28.5 |

| 32 | 1 1/4 | 42.8 | 34.3 | 28.7 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 12.5 | 12.5 | 30.0 |

| 40 | 1 1/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 12.5 | 12.5 | 32.0 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 16.0 | 19.0 | 41.0 |

| 65 | 2 1/2 | 73.9 | 61.2 | / | / | 8.76 | 7.62 | / | / | / | / | 16.0 | 19.0 | 43.0 |

| 80 | 3 | 89.9 | 76.4 | / | / | 9.52 | 8.30 | / | / | / | / | 16.0 | 19.0 | 44.5 |

| 100 | 4 | 115.5 | 100.7 | / | / | 10.69 | 9.35 | / | / | / | / | 19.0 | 19.0 | 48.0 |

Full Coupling 3000

2 Inch Class 3000 Socket Weld Full Coupling ASTM A182 F11 ASME B16.11

USD22 USD20

Threaded Half Coupling

2” Class 6000 Threaded Half Coupling BSPP ASTM A182 F22 ASME B16.11

USD56 USD55