- Home

- Blog Custom Layout

- Threaded Fittings

- Threaded End Cap

Threaded End Cap

USD60 USD58

4" Class 3000 Galvanized BSPP Threaded End Cap ASTM A105 ASME B16.11

- General Details

- Technical Info

- Specification

- Documents

- Related Products

Galvanized Pipe Cap

Threaded end cap is similar with threaded coupling, both of them are available in Class 3000 & 6000. We also call them high pressure forged pipe fittings.

Class 3000 Pipe Fittings, Carbon Steel ASTM A105 Threaded Pipe Cap, 4″ BSPP 90 Degree Elbow with galvanized coating are supplied for Papua New Guinea.

What’s the purpose of galvanized? To extend service lives of threaded forged fittings. Why choose thread connection? Because they have advantages of simple, quick & leak-proof, and ideal for small diameter pipe systems.

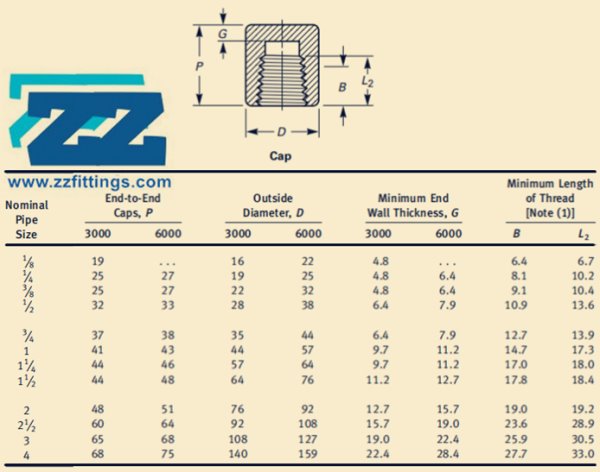

Threaded End Cap Dimensions

Threaded End Cap Dimensions

Standard: ASME B16.11, BS3799

Diameter: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″

Pressure Ratings: 3000LB, 6000LB

Thread Type: NPT, BSPP, BSPT, PT, PF

Surface: Anti-rust Oil, Galvanized or PE Coated.

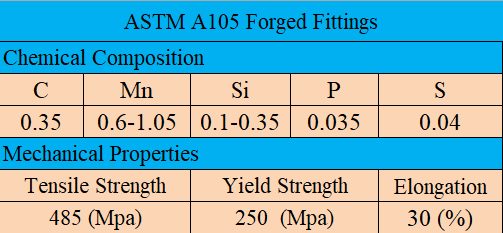

Material Grades of BSP Threaded Fittings

Alloy Steel Threaded End Cap

ASTM A182 F1, F5, F9, F11, F12, F22, F91

Duplex Steel Threaded Pipe Fittings

ASTM A182 F51, F53, F55, S 31803, 32205, 32550, 32750, 32760

Carbon Steel BSP Fittings

ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3

Stainless Steel Forged Fittings

ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321

Class 3000 Threaded Cap Weight

The weight chart covers Class 3000 3000LB and 6000LB threaded pipe cap.

| Nominal Size | Weight/kg | |

| DN | NPS | Class 3000 |

| 6 | 1/8 | 0.03 |

| 8 | 1/4 | 0.05 |

| 10 | 3/8 | 0.1 |

| 15 | 1/2 | 0.2 |

| 20 | 3/4 | 0.3 |

| 25 | 1 | 0.4 |

| 32 | 1 1/4 | 0.7 |

| 40 | 1 1/2 | 0.9 |

| 50 | 2 | 1.3 |

| 65 | 2 1/2 | 2.3 |

| 80 | 3 | 3.3 |

| 100 | 4 | 6.7 |

4 inch Threaded Pipe Cap

Package

We marked all Carbon Steel Threaded Caps with Grade, Lot No, Size, Standard and Pressure. The workers sleeved 4 inch Threaded Cap ASTM A105 into plastic bag individually, put all of them into cartons and wooden cases, then bundled package with nylon rope.

Package of Carbon Steel Threaded Cap

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. Great care is taken during operation and transportation.

Inspection

- Visual the surface of cap body. Such as dents, die marks, porosity, undercuts.

- Check the marking. Such as Size, material code, grade, thickness, heat No.

- Measure dimensions of threaded cap. Such as outside diameter,thickness, height.

- Test thread types with Go/no Go Gauge.

- Test the galvanized thickness of forged steel pipe fittings

Advantages

- ISO certified quality

- Fast delivery

- Safe package

- Offer in time

- Abundant stock

- Reasonable price

- Reliable shipment

ASTM A105 Forged Fittings Datasheet

ASTM A105 Forged Fittings Datasheet

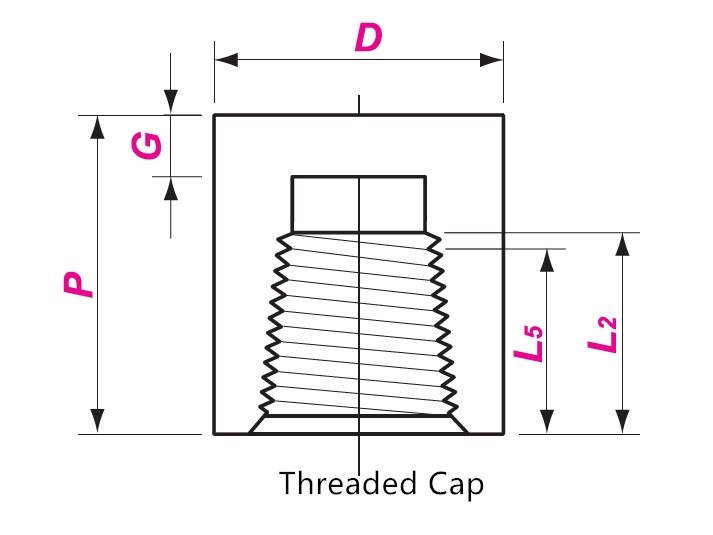

Drawing & Specification for Threaded Cap

Drawing & Specification of Threaded Cap

Thread shall be machined as per ASME B1.20.1.

| Nominal Size | End-to-End | Outside Diameter | End Wall | Length of Thread | |||||

| DN | NPS | P | D | G min | L 5 min | L 2 min | |||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 19 | – | 16 | 22 | 4.8 | – | 6.4 | 6.7 |

| 8 | 1/4 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 10 | 3/8 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 15 | 1/2 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 20 | 3/4 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 25 | 1 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 32 | 1 1/4 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17 | 18 |

| 40 | 1 1/2 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 50 | 2 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19 | 19.2 |

| 65 | 2 1/2 | 60 | 64 | 92 | 108 | 15.7 | 19 | 23.6 | 28.9 |

| 80 | 3 | 65 | 68 | 108 | 127 | 19 | 22.4 | 25.9 | 30.5 |

| 100 | 4 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33 |

8″ Equal Tee ASTM A860 WPHY 65

8" SCH XXS EQUAL TEE SEAMLESS BW ASTM A860 WPHY 65 ASME B16.9

USD190 USD185

Galvanized 90 Degree Elbow

Galvanized 1 Inch BSPP 3000# 90 Degree Elbow ASTM A694 F52 ASME B16.11

USD6 USD5

A182 F316 Threaded Coupling

Full Coupling Threaded 3000 LB BSPP 1 1/2" ASTM A182 F316 ASME B16.11

USD37 USD35