- Home

- Blog Custom Layout

- Stainless Steel Pipe Fittings

- Stainless Steel Socket Weld Fittings

Stainless Steel Socket Weld Fittings

USD60 USD58

304 & 316 Stainless Steel Socket Weld Pipe Fittings Class 3000, 6000, 9000

- General Details

- Chemical Properties

- Dimension Tolerance

- Related Products

Stainless Steel Socket Weld Fittings are family members of high pressure pipe fittings, which available in rating of Class 3000lb, 6000lb and 9000lb. They are used in areas where pipe-work is permanent and are designed to provide good flow characteristics. Usually in conjunction with with ASME Pipe and are available in the same size range.

We produced forged steel fittings in accordance with ASME B16.11. The B16.11 standard covers pressure-temperature ratings, dimensions, tolerances, marking, and material requirements for forged carbon and alloy stainless steel. The chemical and mechanical property requirements are conform to ASTM A105, A182 or A350.

Standard for Stainless Steel Socket Weld Fittings

Forged stainless steel material conforms to ASTM A182

Forged steel fitting dimensions conform to ASME B16.11

Socket weld fittings conform to ASME B16.11

Forged socket weld union conform to MSS SP-83

Stainless steel outlets conform to MSS SP-97

Forged Stainless socket weld inserts conform to MSS SP-79

| Size | 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″ |

| Grade | F304 / 304L / 304H / 316 / 316L / 317 / 317L / 321 / 310 / 347 / 904L |

| Type | Elbow, Tee, Union, Cross, Coupling, Cap, Insert. |

Socket Weld Fittings

SS Socket Weld Elbow

Socket weld elbow can make 45 degree and 90 degree changes the direction in the flow of pipe. You do not need to do bevel weld preparation for pipes. They have same function with threaded fittings.

Stainless Steel Socket Weld Coupling

Socket weld coupling is meant to joint a pipe into a recessed area of valves, fittings and flanges. Full coupling is usually to joint pipe to pipe or nipple, while half coupling is a combination of provision. We can join one end by welding and other side of with socket weld. They are available in various of sizes, thickness, pressure ratings according to customer’s requirements.

SS Socket Weld Cross

Socket weld cross can makes 90 degree branch from the main run of pipe.It is used to change the direction of the line in the piping system.

Stainless Steel Socket Weld Tee

Socket weld tee are mainly forming by the round steel or ingot molding forging, and then machined to be a high-pressure pipeline connection accessories. If the branch diameter is same as run pipe, we call it as SW Equal Tee. Otherwise, it is Socket Weld Reducing Tee.

SS Socket Weld Cap

Socket weld cap is meant to insert a pipe into cap and weld for sealing the pipe end. Same function as threaded plug and blind flange.

Socket Weld Reducing Inserts

Socket weld reducing inserts comply with MSS SP-79 standard. They can make any combination of pipe line reductions quickly and economically.

Difference Between Stainless Steel and Galvanized Steel

Stainless steel has chromium melted into it. This chronium makes it resistant to rust for long time.

Galvanized steel has a coating of zinc on the surface only. Galvanized can be either hot or cold. Hot dipped is where they dip the part into molted zinc. Cold galvanizing is typically done in the field. Cold galvanizing is similar to painting.

Comparing the cost, galvanized steel is cheaper than stainless steel. But the service lift is not longer as stainless steel.

Stainless Steel Socket Weld Fittings VS Cast Fittings

Stainless steel forged socket weld fittings are engineered to be stronger than cast fittings.

Casting is the process where metal is heated until molten. While in the molten or liquid state it is poured into a mold or vessel to create a desired shape.

Forging is the application of thermal and mechanical energy to steel billets or ingots to cause the material to change shape while in a solid state.This process alters the grain of the steel causing it to be mechanically stronger and more reliable with a high impact tolerance. Forged steel also has a high wear resistance because of the tighter grain structure of the steel.

What is the differences between Socket Weld and Butt Weld?

When the pipes are inserted into socket weld pipe fitting, and then welding them together. So the inside diameter of SW fittings is a little larger than pipe outside diameter. Butt welding is much more difficult and your welder should have a good technical skill. Normally pipes welded on pipes or buttweld fittings or flanges. There is no room for error in this way.

| Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| ASTM A182 F304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 8.0-11.0 | 18.0-20.0 | |

| ASTM A182 F304H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 8.0-11.0 | 18.0-20.0 | |

| ASTM A182 F304L | 0.03 | 2 | 0.045 | 0.03 | 1 | 8.0-13.0 | 18.0-20.0 | |

| ASTM A182 F309H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 12.0-15.0 | 22.0-24.0 | |

| ASTM A182 F310 | 0.25 | 2 | 0.045 | 0.03 | 1 | 19.0-22.0 | 24.0-26.0 | |

| ASTM A182 F310H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 19.0-22.0 | 24.0-26.0 | |

| ASTM A182 F316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| ASTM A182 F316H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| ASTM A182 F316L | 0.03 | 2 | 0.045 | 0.03 | 1 | 10.0-15.0 | 16.0-18.0 | 2.0-3.0 |

| ASTM A182 F317 | 0.08 | 2 | 0.045 | 0.03 | 1 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 |

| ASTM A182 F317L | 0.03 | 2 | 0.045 | 0.03 | 1 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 |

| ASTM A182 F321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 9.0-12.0 | 17.0-19.0 | |

| ASTM A182 F321H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 9.0-12.0 | 17.0-19.0 | |

| ASTM A182 F347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 9.0-13.0 | 17.0-20.0 | |

| ASTM A182 F347H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 9.0-13.0 | 17.0-20.0 | |

| ASTM A182 F348 | 0.08 | 2 | 0.045 | 0.03 | 1 | 9.0-13.0 | 17.0-20.0 | |

| ASTM A182 F348H | 0.04-0.10 | 2 | 0.045 | 0.03 | 1 | 9.0-13.0 | 17.0-20.0 |

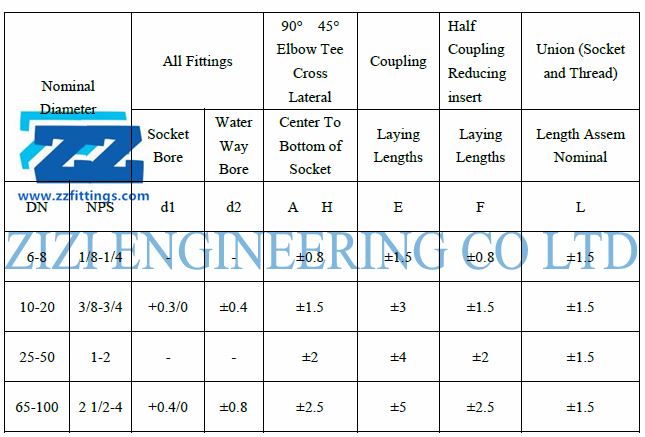

Socket Weld Fittings Dimension Tolerance Chart

Class 3000 Socket Weld Fittings

Socket Weld Fittings 1" Class 3000 Elbow ASTM A182 F316 ASME B16.11

USD16 USD15

Threaded Pipe Nipples

Nipple 1/2" Sch 80 BSPP TBE L=100MM Galvanized API 5LB ASME B16.11

USD2.5 USD2

Full Coupling 3000

2 Inch Class 3000 Socket Weld Full Coupling ASTM A182 F11 ASME B16.11

USD22 USD20

A182 F316 Threaded Coupling

Full Coupling Threaded 3000 LB BSPP 1 1/2" ASTM A182 F316 ASME B16.11

USD37 USD35