- Home

- Blog Custom Layout

- Forged Steel Olets

- SS 316L Sockolet

SS 316L Sockolet

USD21 USD20

12 x 2 Inch Class 3000 Sockolet ASTM A182 SS 316L MSS SP-97

- General Details

- Technical Info

- Specification

- Documents

- Related Products

Stainless Steel Sockolet Manufacturers

High quality SS 316L Sockolet manufacturer, supplier and trader in China, offers best price branch outlet fittings in any sizes according to ASME and MSS. No limitation on the quantity and materials.

316 Stainless Steel sockolet is an integrally reinforce branch olet fittings that more safe and reliable than other traditional branch connection fittings. The advantages of easy usage, good performance and durable make it highly demanded by customers.

Stainless Steel Outlets Fittings

SS 316L Sockolet Dimensions

SS 316L Sockolet Dimensions

Standard: MSS-SP-97

Run Pipes Diameter Range: DN8– 900 / NPS1/4 – 36

Branch Diameter Range: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″

Pressure Rate: Class 3000 and Class 6000

Surface: Anti-rust Oil and Galvanized.

Sockolet Weight Chart

The sockolet weight chart is covering Class 3000lb & 6000lb and weight unit is kg.

| DN | NPS | 3000LB | 6000LB |

| 6 | 1/8 | 0.05 | / |

| 8 | 1/4 | 0.05 | |

| 10 | 3/8 | 0.09 | / |

| 15 | 1/2 | 0.14 | 0.36 |

| 20 | 3/4 | 0.16 | 0.47 |

| 25 | 1 | 0.27 | 0.68 |

| 32 | 1 1/4 | 0.39 | 1.1 |

| 40 | 1 1/2 | 45 | 1.3 |

| 50 | 2 | 0.73 | 2.45 |

| 65 | 2 1/2 | 125 | / |

| 80 | 3 | 1.72 | / |

| 90 | 3 1/2 | 1.95 | / |

| 100 | 4 | 3.29 | / |

Material Grades of Sockolet MSS SP-97

Duplex Steel Olets

ASTM A182 F51, F53, F55, S 31803, S 32205, S 32550, S 32750, S 32760

Stainless Steel Pipe Fittings

ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321, F309

ASTM A182 F1, F5, F9, F11, F12, F22, F91

Carbon Steel Socket Weld Fittings

ASTM A105, A350 LF2, LF3, A694 F52, F60, F65, F70

SS 316 and SS 316L

SS316 is one of the most popular stainless steel grade that often used for atmospheric and other mild types of corrosion applications. It performs well in normal and high temperature pipe systems.

SS316L is a low carbon type 316 stainless steel. With similar properties, it provides more excellent corrosion resistance, especially its resistance Intergranular Corrosion. Because it is difficult to keep the carbon in less content, SS 316L fittings have higher prices.

Package of Stainless Steel 316L Pipe Fittings

We marked all stainless steel forged branch connection fittings with Size, Pressure, Grade and Heat No. All SS 316L Sockolet is surfaced with oil before delivery. The workers sleeved stainless steel sockolets into plastic bag individually, packed them in carton and wooden cases, then bundled packages with nylon rope.

Stainless Steel Socket Weld Fittings Package

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. great care is taken during operation and transportation.

Inspection Process for Forged Steel Sockolet

- Visual the surface of socket weld Pipe fittings body.

- Measure dimensions. Such as diameter, wall thickness, and dimensions of the socket.

- Check the marking “ 12″ x 2″ 3000 A182 F316L MSS SP-97 Z168″

SS 316L Pipe Fittings

Chemical Composition,%

| C | Mn | P | S | Si | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 0.03 | 2.0 | 0.045 | 0.03 | 1.0 | 10-14 | 16-18 | 2-3 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 485(Mpa) | 170(Mpa) | 35(%) |

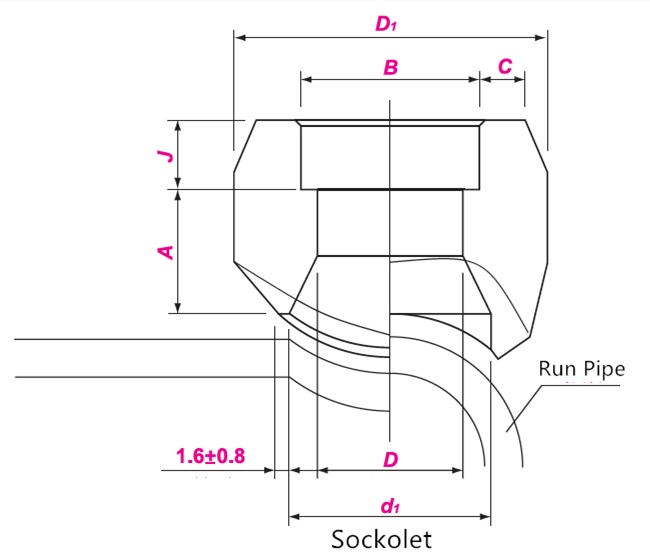

Drawing & Specification Details for Sockolet

Sockolet Drawing

| Nominal Size | Branch Nominal Size | Depth of Socket | Face of Fitting to Crotch | OD of Fitting | Socket Wall Thickness | Cut Hole Dia. | ||||||

| DN | NPS | DN | NPS | J min | A max | D 1 min | C min | d 1 nom | ||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | |||||

| 8~900 | 1/4~36 | 6 | 1/8 | 9.5 | 10 | – | 27 | – | 3.18 | – | 16 | – |

| 10~900 | 3/8~36 | 8 | 1/4 | 9.5 | 10 | – | 27 | – | 3.78 | – | 16 | – |

| 15~900 | 1/2~36 | 10 | 3/8 | 9.5 | 13 | – | 30 | – | 4.01 | – | 19 | – |

| 20~900 | 3/4~36 | 15 | 1/2 | 9.5 | 16 | 24 | 38 | 47 | 4.67 | 5.97 | 24 | 19 |

| 25~900 | 1~36 | 20 | 3/4 | 12.5 | 16 | 25 | 47 | 53 | 4.9 | 6.96 | 30 | 25 |

| 32~900 | 1 1/4~36 | 25 | 1 | 12.5 | 22 | 29 | 56 | 63 | 5.69 | 7.92 | 36 | 33 |

| 40~900 | 1 1/2~36 | 32 | 1 1/4 | 12.5 | 22 | 30 | 66 | 74 | 6.07 | 7.92 | 45 | 38 |

| 50~900 | 2~36 | 40 | 1 1/2 | 12.5 | 24 | 32 | 75 | 83 | 6.35 | 8.92 | 51 | 49 |

| 65~900 | 2 1/2~36 | 50 | 2 | 16 | 24 | 37 | 90 | 104 | 6.93 | 10.92 | 65 | 59 |

| 80~900 | 3~36 | 65 | 2 1/2 | 16 | 25 | – | 105 | – | 8.76 | – | 76 | – |

| 100~900 | 4~36 | 80 | 3 | 16 | 30 | – | 124 | – | 9.52 | – | 94 | – |

| 125~900 | 5~36 | 100 | 4 | 19 | 30 | – | 154 | – | 10.69 | – | 121 | – |

Threaded Socket & Coupling

Threaded socket coupling 1 1/2" Class 3000 BSPP SS316 ASME B16.11

USD30 USD28

45 Degree Long Radius Elbow

6” STD 45 Degree Long Radius Elbow Seamless ASTM A420 WPL6 ASME B16.9

USD8 USD7

Socket Weld Half Coupling

2 Inch Class 6000 Socket Weld Half Coupling ASTM A105 ASME B16.11

USD12 USD11

Alloy Steel Forged Fittings

Elbow, Tee, Coupling, Cap, Plug, Bushing, Union, Nipple, Forged Steel Olets

USD500 USD350