- Home

- Blog Custom Layout

- Steel Pipe Couplings

- Threaded Socket & Coupling

Threaded Socket & Coupling

USD30 USD28

Threaded socket coupling 1 1/2" Class 3000 BSPP SS316 ASME B16.11

- General Details

- Technical Info

- DWG & SPEC

- Documents

- Related Products

Threaded socket is commonly called threaded coupling and used to connect with the steel tubes. There are two mainly threads which are BSP and NPT.

As a top class manufacturer of stainless steel forged fittings, Zizi exports A182 F316 threaded socket & coupling 1 1/2″ Class 3000 BSPP ASME B16.11 for Southeast Asia. They are in safety package and combine with other goods in 20ft container.

Forged Fittings Types

- Socket Weld Fittings

Elbow, Tee, Cross, Cap, Coupling, Union, Lateral and Reducing Socket Inserts.

- Threaded Pipe Fittings

Elbow, Tee, Cross, Cap, Coupling, Plug, Hexagonal Nipple and Union.

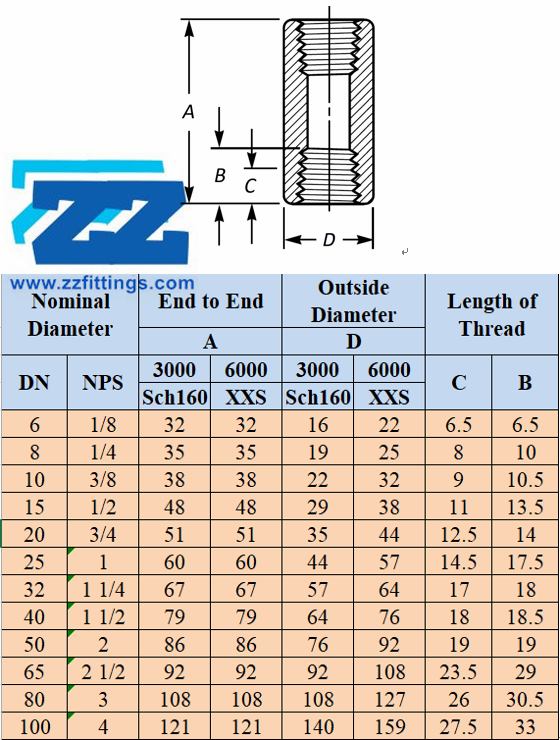

Threaded Socket & Coupling Dimensions

Threaded Socket Dimensions

Standard: ASME B16.11, BS3799, GB/T14626

Diameter: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″

Pressure Ratings: 2000LB, 3000LB, 6000LB

Thread Type: NPT, BSPP, BSPT, PT, PF

Surface: Anti-rust Oil and Galvanized

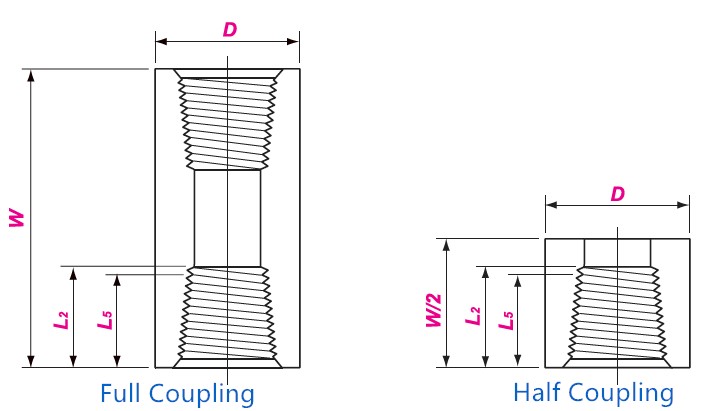

How Many Types for Threaded Pipe Coupling?

Threaded Half Coupling & Full Coupling.

BSP Coupling & NPT Coupling.

Straight Coupling & Reducing Coupling.

Material Grades of BSP Socket

Alloy Steel Threaded Coupling

ASTM A182 F1, F5, F9, F11, F12, F22, F91

Duplex Steel Pipe Coupling

ASTM A182 F51, F53, F55, S 31803, S 32205, S 32550, S 32750, S 32760

Carbon Steel Threaded Fittings

ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3

Stainless Steel Forged Fittings

ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321,F947

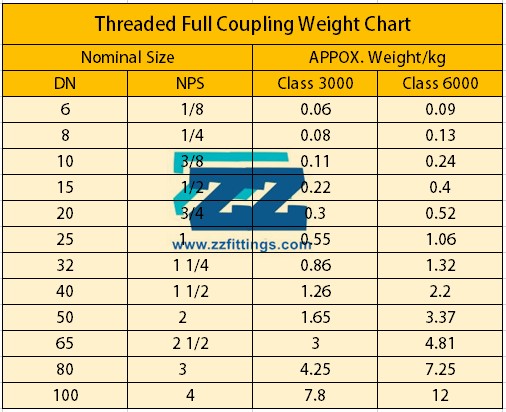

Threaded Full Coupling Weight Chart

Threaded Coupling Weight

BSP Pipe Fittings

Package for Stainless Steel Threaded Fittings

We marked all Stainless Steel Threaded Fittings with Grade, Lot No, Size, Standard and Pressure. The workers sleeved 1 1/2″ BSP Threaded Coupling SS 316 into plastic bag individually, put all of them into cartons and wooden cases, then bundled package with nylon rope.

Clear labels are tagged on the outside of the package for easy identification of the quantity and product. Great care is taken during operation and transportation.

Inspection & Marking for Threaded Coupling

- Visual the surface of threaded coupling. Such as dents, die marks, porosity, undercuts.

- Check the marking ” 1 1/2″ 3000# BSPP SS316 ASME B16.11 Z168″

- Measure dimensions. Such as outside diameter, thread length, height from end to end.

- Test the chemical composition of stainless steel threaded couplings.

- Test the thread by go/no gauge

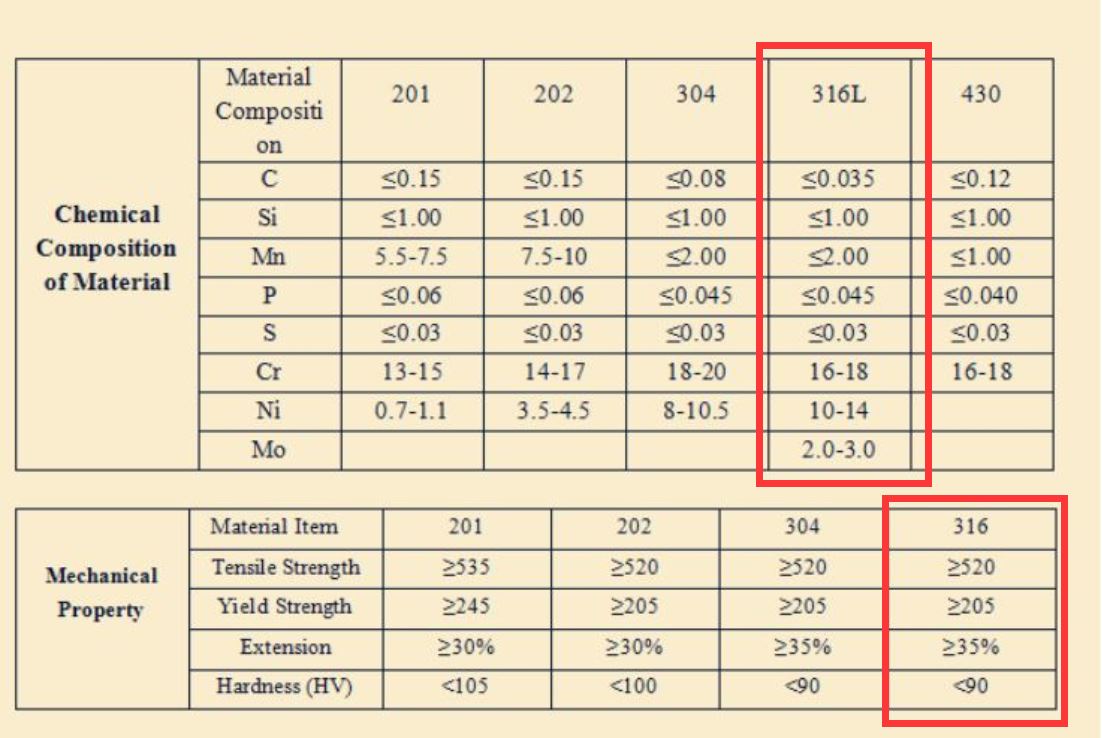

Stainless Steel 316 Chemical and Mechanical Properties

Stainless Steel 316 Chemical and Mechanical Properties

Drawing & Specification for ASME B16.11 Threaded Coupling

Threaded Coupling Drawing

| Nominal Size | End-to-End | Outside Diameter | Length of Thread | |||

| NPS | DN | W | D | L 5 min | L 2 min | |

| 3000 & 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 32 | 16 | 22 | 6.4 | 6.7 |

| 8 | 1/4 | 35 | 19 | 25 | 8.1 | 10.2 |

| 10 | 3/8 | 38 | 22 | 32 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 28 | 38 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 35 | 44 | 12.7 | 13.9 |

| 25 | 1 | 60 | 44 | 57 | 14.7 | 17.3 |

| 32 | 1 1/4 | 67 | 57 | 64 | 17 | 18 |

| 40 | 1 1/2 | 79 | 64 | 76 | 17.8 | 18.4 |

| 50 | 2 | 86 | 76 | 92 | 19 | 19.2 |

| 65 | 2 1/2 | 92 | 92 | 108 | 23.6 | 28.9 |

| 80 | 3 | 108 | 108 | 127 | 25.9 | 30.5 |

| 100 | 4 | 121 | 68 | 75 | 140 | 159 |

Stainless Steel Bushings

3/4 x 1/2 NPT Stainless Steel 304L Flush Bushing Reducer ASME B16.11

USD6 USD5

Threaded Half Coupling

2” Class 6000 Threaded Half Coupling BSPP ASTM A182 F22 ASME B16.11

USD56 USD55