The 90 degree elbow is a crucial pipe fitting in the piping system. It is used to connect two sections of pipes or pipe fittings to form a continuous, changing direction fluid passage. Its core function is to change the flow direction of the fluid in the pipe, making it turn precisely 90 degrees, that is, forming a right-angle bend. The most direct and important function is to achieve a 90-degree change in the direction of the pipe. It is extremely common in various industrial, commercial and civil pipeline applications.

With the 90 degree elbow widely used in the industrial field, it has been used in many municipal project construction and liquid and gas transportation, connecting pipeline projects accordingly to ensure the rationality of energy transportation and construction planning. Since some liquid transportation has strict requirements on pipelines, elbow products have been continuously changed and developed, through hot and cold processes, impact effects, and electric welding processes, making elbow products more suitable for the transportation of pipeline systems.

Long Radius (LR) 90° Elbow:

The radius of curvature (R) is 1.5 times the nominal pipe size (NPS) or outside diameter (D). (R = 1.5D). This provides a smoother turn, reducing friction, turbulence, and pressure drop. It’s generally preferred when space allows and flow efficiency is critical.

Short Radius (SR) 90° Elbow:

The radius of curvature (R) is equal to the nominal pipe size (NPS) or outside diameter (D). (R = 1.0D). This results in a sharper turn, increasing turbulence and pressure drop, but it is more compact and suitable for tight spaces where a smaller bend is necessary.

Features of 90 Degree Elbow

1. Since most pipe fittings are used for welding, in order to improve the welding quality, the ends are beveled, leaving a certain angle and a certain edge. This requirement is also relatively strict. The thickness of the edge, the angle and the deviation range are all specified. The surface quality and mechanical properties are basically the same as those of the pipe. In order to facilitate welding, the steel type of the pipe fittings and the connected pipes are the same.

2. That is, all pipe fittings must be surface treated, and the iron oxide scale on the inner and outer surfaces must be sprayed off by shot peening, and then coated with anti-corrosion paint.

3. The requirements for packaging For small pipe fittings, such as export, wooden boxes of about 1 cubic meter are required. It is stipulated that the number of elbows in such boxes cannot exceed about one ton. The standard allows sets, that is, large sets of small, but the total weight generally cannot exceed 1 ton. For large pieces, they must be packaged individually, such as 24″, which must be packaged individually. In addition, there is the packaging mark, which is to indicate the size, steel grade, batch number, manufacturer’s trademark, etc.

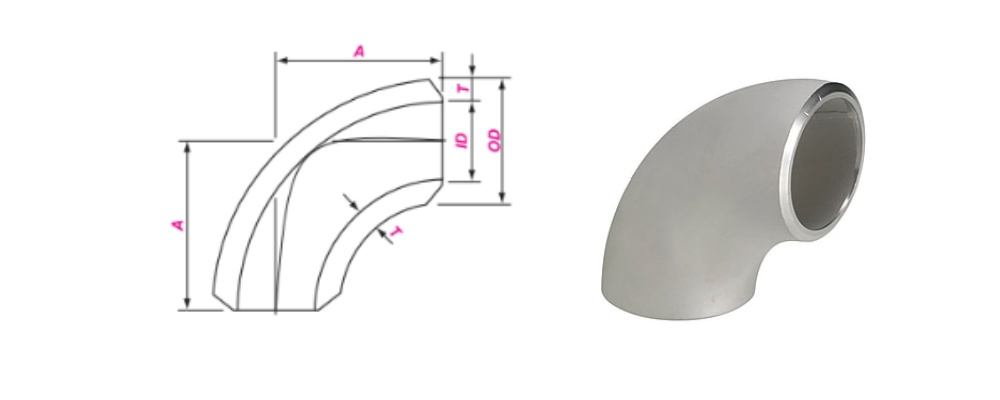

Butt Weld 90 Degree Elbow

Beveled ends for direct welding to the pipe, offering a strong, leak-proof, and smooth internal flow path. Often used for larger diameters and high-pressure/temperature applications.

| Nominal Size | Outside Diameter at Bevel | Center to End | ||

| 90° Elbows | ||||

| DN | NPS | OD | A | |

| LR | SR | |||

| 15 | 1/2 | 21.3 | 38 | |

| 20 | 3/4 | 26.7 | 38 | |

| 25 | 1 | 33.4 | 38 | 25 |

| 32 | 1 1/4 | 42.2 | 48 | 32 |

| 40 | 1 1/2 | 48.3 | 57 | 38 |

| 50 | 2 | 60.3 | 76 | 51 |

| 65 | 2 1/2 | 73.0 | 95 | 64 |

| 80 | 3 | 88.9 | 114 | 76 |

| 90 | 3 1/2 | 101.6 | 133 | 4、89 |

| 100 | 4 | 114.3 | 152 | 102 |

| 125 | 5 | 141.3 | 190 | 127 |

| 150 | 6 | 168.3 | 229 | 152 |

| 200 | 8 | 219.1 | 305 | 203 |

| 250 | 10 | 273.0 | 381 | 254 |

| 300 | 12 | 323.8 | 457 | 305 |

| 350 | 14 | 355.6 | 533 | 356 |

| 400 | 16 | 406.4 | 610 | 406 |

| 450 | 18 | 457.0 | 686 | 457 |

| 500 | 20 | 508.0 | 762 | 508 |

| 550 | 22 | 559.0 | 838 | 559 |

| 600 | 24 | 610.0 | 914 | 610 |

| 650 | 26 | 660.0 | 991 | 660 |

| 700 | 28 | 711.0 | 1067 | 711 |

| 750 | 30 | 762.0 | 1143 | 762 |

| 800 | 32 | 813.0 | 1219 | 813 |

| 850 | 34 | 864.0 | 1295 | 864 |

| 900 | 36 | 914.0 | 1372 | 914 |

| 950 | 38 | 965.0 | 1448 | 965 |

| 1000 | 40 | 1016.0 | 1524 | 1016 |

| 1050 | 42 | 1067.0 | 1600 | 1067 |

| 1100 | 44 | 1118.0 | 1676 | 1118 |

| 1150 | 46 | 1168.0 | 1753 | 1168 |

| 1200 | 48 | 1219.0 | 1829 | 1219 |

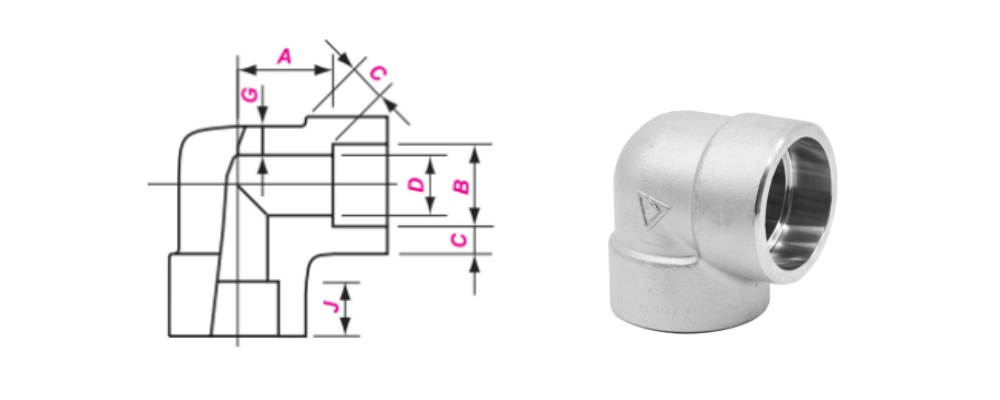

Socket Weld 90 Degree Elbow

Features a socket into which the pipe is inserted and then externally fillet welded. Suitable for small-bore, high-pressure systems where a smooth internal flow is desirable (weld is outside).

| Nominal Size | Socket Bore Dia. | Bore Dia. of Fittings | Socket Wall Thickness | Body Wall | Depth of Socket | Center to Bottom of Socket | ||||||||||||

| DN | NPS | B | D | C | G min | J min | A | |||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 90 Elbow,Tee,Cross | |||||||||

| ave | min | ave | min | ave | min | 3000 | 6000 | 9000 | ||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | 3.18 | 3.18 | 3.96 | 3.43 | 2.41 | 3.15 | 9.5 | 11 | 11 | |||||

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | 3.78 | 3.3 | 4.6 | 4.01 | 3.02 | 3.68 | 9.5 | 11 | 13.5 | |||||

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | 4.01 | 3.5 | 5.03 | 4.37 | 3.2 | 4.01 | 9.5 | 13.5 | 15.5 | |||||

| 15 | 1/2 | 21.9 | 15 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19 | 25.5 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19 | 22.5 | 28.5 |

| 25 | 1 | 34 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27 | 32 |

| 32 | 11/4 | 42.8 | 34.3 | 28.7 | 22 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 | 27 | 32 | 35 |

| 40 | 11/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32 | 38 | 38 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 | 38 | 41 | 54 |

| 65 | 21/2 | 73.9 | 61.2 | 8.76 | 7.62 | 7.01 | 16 | 41 | ||||||||||

| 80 | 3 | 89.9 | 76.4 | 9.52 | 8.3 | 7.62 | 16 | 57 | ||||||||||

| 100 | 4 | 115.5 | 100.7 | 10.69 | 9.35 | 8.56 | 19 | 66.5 | ||||||||||

Threaded 90 Degree Elbow

Possesses internal or external threads for mechanical connection to threaded pipes. Valued for ease of installation and disassembly in low-to-medium pressure, smaller diameter lines.

| Nominal Size | Center-to-End | Outside Diameter of Band | Wall Thickness | Length of Thread | ||||||||

| DN | NPS | A | H | G min | L5 min | L2 min | ||||||

| 90° Elbows | ||||||||||||

| 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | ||||

| 6 | 1/8 1/4 3/8 | 21 | 21 | 25 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 21 | 25 | 28 | 22 | 25 | 33 | 3.18 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 25 | 28 | 33 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 28 | 33 | 38 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 33 | 38 | 44 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 38 | 44 | 51 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 1 1/4 | 44 | 51 | 60 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 1 1/2 | 51 | 60 | 64 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 60 | 64 | 53 | 75 | 84 | 102 | 4.27 | 7.14 | 12.09 | 19.0 | 19.2 |

| 65 | 2 1/2 | 76 | 83 | 95 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

| 80 | 3 | 86 | 95 | 106 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 106 | 114 | 114 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33 |

Materials:

90 degree elbows are manufactured from a wide range of materials to suit different applications, media, and pressure/temperature requirements. Common materials include:

Stainless Steel (e.g., 304, 304L, 316, 316L)

Carbon Steel (e.g., A234 WPB)

Alloy Steel

Copper

PVC (Polyvinyl Chloride)

CPVC (Chlorinated Polyvinyl Chloride)

Brass

Cast Iron

Applications:

90-degree elbows are fundamental components across numerous industries:

Plumbing and Drainage: Residential and commercial water supply, waste lines.

HVAC Systems: Air handling and ventilation ducts.

Oil and Gas Industry: Refineries, pipelines, offshore platforms.

Chemical and Petrochemical Plants: For processing and conveying various chemicals.

Power Generation: In steam lines, cooling water systems.

Food Processing and Pharmaceutical: For hygienic and corrosion-resistant piping.

General Industrial Use: Any system requiring a 90-degree change in fluid direction.

Our Supply Range For Elbows

For Butt Weld Elbow

Manufacturing Standard: ANSI / ASME B16.9, MSS SP 43, JIS B2311/2312/2313, EN10253

Types: 45 degree steel elbow, 90 degree steel pipe elbow, 180 degree elbow

Size Range: 1/2”, 1”, 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16”, 20” to 48”.

Thickness: SCH 10, SCH 40, SCH 80

Surface Coatings: Black Painted, Varnished, Epoxy Coated, Galvanized

For Socket Weld Elbow and Threaded Elbow

Manufacturing Standard: ASME B16.11, BS3799

Dimensions: 1/2”, 1”, 1/2”, 2” and up to 4”

Pressure Ratings: 2000#, 3000#, 6000#, 9000#

Conclusion:

In summary, 90 degree elbows are essential fittings in piping systems that are used to change the direction of a pipe by 90 degrees. Their composition varies depending on the materials used, making them ideal for numerous applications such as power plants, chemical plants, and oil and gas. Choosing the right elbow can improve system efficiency, reduce friction losses, and extend the life of the piping system. The durability and corrosion resistance of 90 degree elbows make them a versatile fitting that plays an important role in connecting, redirecting, and changing the direction of piping systems.