- Home

- Blog Custom Layout

- Stub Ends

- Type A Stub End

Type A Stub End

USD65 USD63

6” Sch 40S Type A Stub End Seamless ASTM A403 WP316L MSS SP-43

- General Details

- Technical

- Dimensions

- Video

- Documents

- Related Products

Stub End Supplier

Type A Stub End is one type of butt weld pipe fittings, and always supplied with lap joint flanges, they are in variety of dimensions and materials. Why choose us? International manufacturing standards and experienced production, and the most is ISO certified manufacturer. So we will check and keep every piece of products that have quality assurance.

Furthermore, our warehouse is located in Shanghai so that we can ship your goods as soon as possible.

Stub End and Lap Joint Flange

Stub End Type A is most suitable for use with standard lap joint flanges. It has outside corner radius to receive lap joint flanges, and the inside corner is square. Stub ends are not contact with fluids conveyed by the pipeline. To reduce the total weight and cost, so you can use carbon steel stub end with stainless steel lap joint flanges.

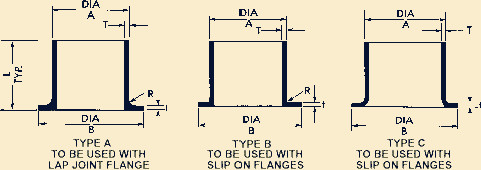

MSS-SP-43 also covers other stub end types, they are suitable for different flanges.

Stub End Type

Material Grades of MSS Lap Joint Stub Ends

Carbon Steel Stub End

ASTM A234 WPB, A860 WPHY42, WHPY52, WPHY60, WHPY65, WPHY70, A420 WPL 3 / 6/ 9

Stainless Steel Fittings

ASTM A403 WP304/304L, WP304H, WP316/316L, WP310, WP317, WP321, WP309

Alloy Steel Pipe Fittings

ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Duplex Steel Pipe Fittings

ASTM A815 UNS S31803, S32205, S32550, S32750, S32760

MSS Type A Stub End Dimensions

Standard: MSS SP-43

Size Range: 1/2″ to 24″ / DN15 to DN600

Thickness: Sch 10s, 20, STD, 40S, 80S, 160, XXS

Type: Long Pattern and Short Pattern Stub End

Length: Standard Length or customized length.

Package of Stainless Steel Buttweld Fittings

We marked Stainless Steel Stub Ends with Material Grade, Lot No, Size, Standard and Thickness. Our workers will pack ASTM A403 WP316L Type A Stub End into wooden cases with protection.

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D.

Additional Services

Commercial Invoice

Packing List

Bill of Loading

Certificate of Origin

Mill Test Certificate

Shipping Service.

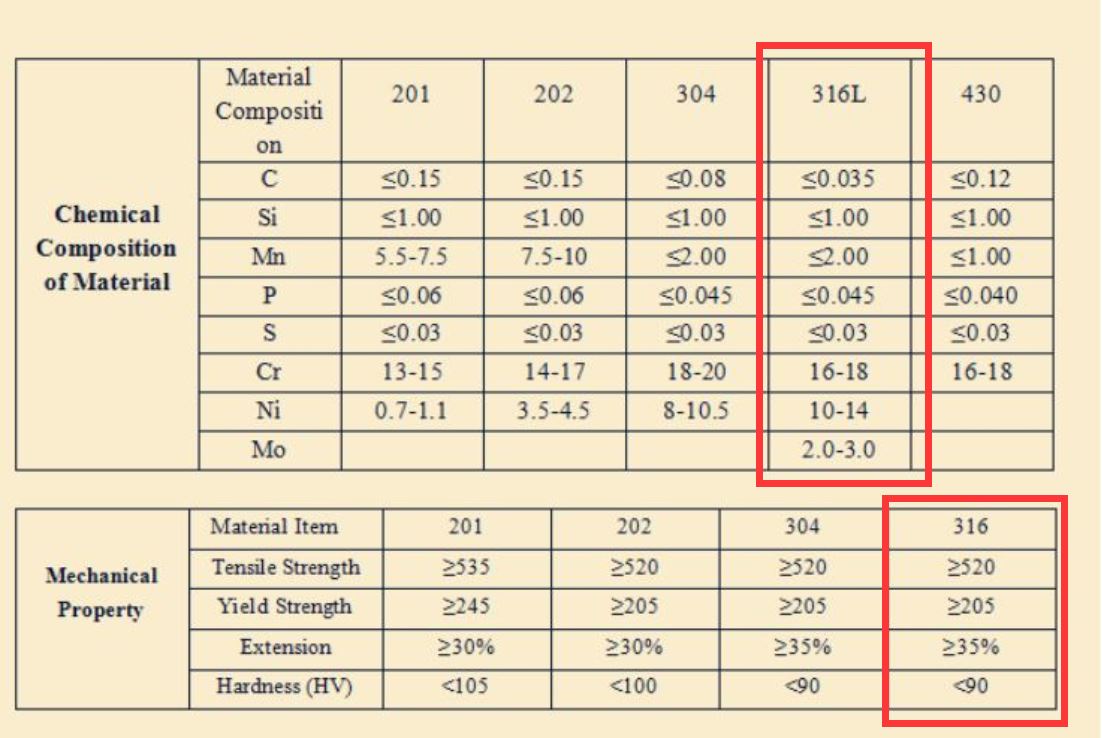

Stainless Steel 316L Pipe Fittings

Stainless Steel 316 Chemical and Mechanical Properties

ASME B16.9 & MSS SP 43 Stub End

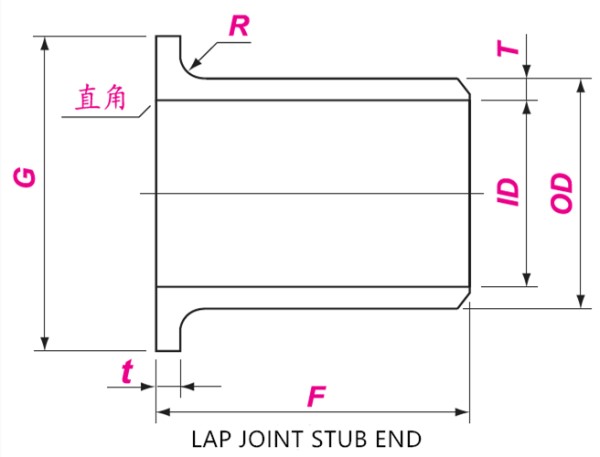

Lap Joint Stud End Drawing

| Nominal Size | OD of Cylinder | Length | Radius of Fillet | Diameter of Lap | ||||

| OD | F | R | ||||||

| DN | NPS | Max. | Min. | Long Type | Short Type | A | Bmax | G |

| 15 | 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 0.8 | 35 |

| 20 | 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 0.8 | 43 |

| 25 | 1 | 35 | 32.6 | 102 | 51 | 3 | 0.8 | 51 |

| 32 | 1 1/4 | 43.6 | 41.4 | 102 | 51 | 5 | 0.8 | 64 |

| 40 | 1 1/2 | 49.9 | 47.5 | 102 | 51 | 6 | 0.8 | 73 |

| 50 | 2 | 62.4 | 59.5 | 152 | 64 | 8 | 0.8 | 92 |

| 65 | 2 1/2 | 75.3 | 72.2 | 152 | 64 | 8 | 0.8 | 105 |

| 80 | 3 | 91.3 | 88.1 | 152 | 64 | 10 | 0.8 | 127 |

| 90 | 3 1/2 | 104 | 100.8 | 152 | 76 | 10 | 0.8 | 140 |

| 100 | 4 | 116.7 | 113.5 | 152 | 76 | 11 | 0.8 | 157 |

| 125 | 5 | 144.3 | 140.5 | 203 | 76 | 11 | 1.6 | 186 |

| 150 | 6 | 171.3 | 167.5 | 203 | 89 | 13 | 1.6 | 216 |

| 200 | 8 | 222.1 | 218.3 | 203 | 102 | 13 | 1.6 | 270 |

| 250 | 10 | 277.2 | 272.3 | 254 | 127 | 13 | 1.6 | 324 |

| 300 | 12 | 328 | 323.1 | 254 | 152 | 13 | 1.6 | 381 |

| 350 | 14 | 359.9 | 354.8 | 305 | 152 | 13 | 1.6 | 413 |

| 400 | 16 | 411 | 405.6 | 305 | 152 | 13 | 1.6 | 470 |

| 450 | 18 | 462 | 456 | 305 | 152 | 13 | 1.6 | 533 |

| 500 | 20 | 514 | 507 | 305 | 152 | 13 | 1.6 | 584 |

| 550 | 22 | 565 | 558 | 305 | 152 | 13 | 1.6 | 641 |

| 600 | 24 | 616 | 609 | 305 | 152 | 13 | 1.6 | 692 |

When the short type is used on the larger flanges with PN 50 and PN 110 (300 and 600 LB) and on flanges with PN 150(900 LB) and above, or the long type is used on the larger flange with PN 260 and PN 420(1500 and 2500LB), the length of the cylinder may be added to be feasible the welding, the adding length shall be negotiated by manufacturer and purchaser.

2) The thickness of joint shall be added if the TG and MFM contact surface of flange are used, and the adding thickness shall increase (not be included in) the base length F.

3) The radius of fillet R(type A) shall conform to the ones of loose flanges according to GB/T 9118.19118.2 or ASME B16.5. The radius of fillet R (type B) is only applied for the standards of MSS SP-43 with short length F.

4) The lap joint diameter G shall conform to the standard machined face indicated in ASME B16.5 , and the back of joint shall be machined to conform to the surface of installation.When RJ used, the size K specified in ASME B 16.5 Shall apply.

5) The minimum lap joint thickness t shall not be less than the nominal pipe wall thickness.

ASME B16.9 Lap Joint Stub End

Stainless Steel Equal Tee

6 Inch Sch 80S Equal Tee Stainless Steel ASTM A403 WP316 ASME B36.19

USD238 USD235

Stainless Steel Elbow

Elbow 90 Degree LR DN200 Sch 10S PE Coated A403 WP316 ASME B36.19

USD115 USD111

Swage Nipple A106

3 x 2 Inch Sch 40 Eccentric Swage Nipple NPTM x NPTF ASTM A106 B MSS-SP-95

USD26 USD25

Threaded Hex Head Bushing

Threaded Hex Head Bushing 3/8″×1/4″ BSPT ASTM A105 ASME B16.11

USD0.7 USD0.6

8 Inch Pipe Cap A403 WP304

8 Inch Steel Pipe Cap Sch40S Seamless BW ASTM A403 WP304 ASME B16.9

USD37 USD36

ASTM A105 Reducing Tee Galvanized

Reducing Tee SW DN40 X DN32 Class 3000 Galvanized ASTM A105 ASME B16.11

USD19 USD18