- Home

- Blog Custom Layout

- Forged Steel Olets

- Threadolet BSP

Threadolet BSP

- General Details

- Technical Info

- Specification

- Video

- Documents

- Related Products

Threadolet Suppliers

Threadolet is one type of outlets and commonly machined into BSP & NPT threads, same as other forged steel threaded pipe fittings.

Leading producer, supplier and exporter of high quality Threadolet BSP in best price. For the purpose of providing you the best product, we strict control every stage from material to the package.

MSS-SP-97 threadolet fittings are all certified, you can select what you need and use them in chemical, petrol, gas, power plant and other industries with ease. Besides, with rich production and export experience, no matter the quantity is large or small, we supply you best forged steel olets as fast as possible.

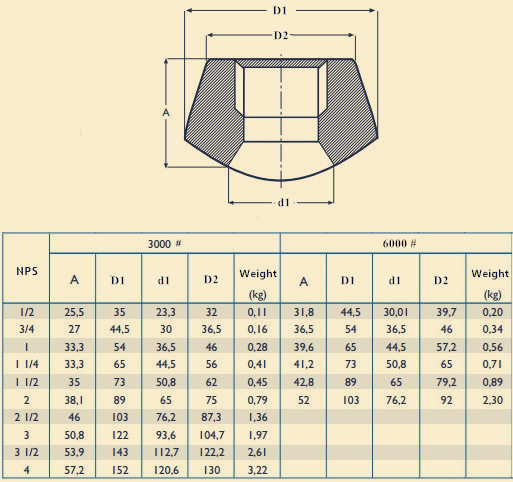

Threadolet BSP Dimensions

Threadolet Dimensions

Standard: MSS-SP-97, ASME B16.11

Run Pipes diameter range: DN8– 300 / NPS1/4 – 36

Branch diameter range: DN6-100/ NPS 1/8-4

Pressure rate: 3000# and 6000#

BSP Thread: BSPP (Parallel), BSPT (Taper).

Threadolet Weight Chart

Threaded outlets are forged fittings and weight is very light.

| DN | NPS | 3000 | 6000 |

| 6 | 1/8 | 0.05 | – |

| 8 | 1/4 | 0.05 | – |

| 10 | 3/8 | 0.09 | – |

| 15 | 1/2 | 0.17 | 0.32 |

| 20 | 3/4 | 0.22 | 0.47 |

| 25 | 1 | 0.43 | 0.65 |

| 32 | 1 1/4 | 0.61 | 0.96 |

| 40 | 1 1/2 | 0.69 | 1.28 |

| 50 | 2 | 1.10 | 2.15 |

| 65 | 2 1/2 | 1.52 | – |

| 80 | 3 | 2.50 | – |

| 100 | 4 | 4.10 | – |

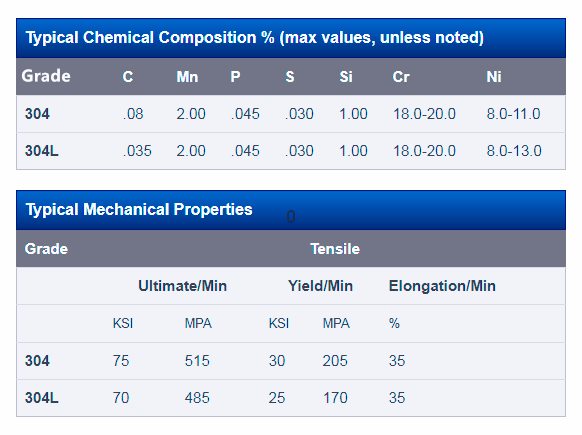

Material Grades of Threadolet Fittings

Duplex Steel Threadolet

ASTM A182 F51, F53, F55, F56, F57

Alloy Steel Threadolet

ASTM A182 F1, F5, F9, F11, F12, F22, F91

Carbon Steel Threadolet

ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3

Stainless Steel Threadolet

ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321, F309

How to Pack Forged Steel Olets?

Before packing, we will do the marking on outlet fittings body which including size, pressure, standard and Heat No. After that, surfaced the forged steel olets with anti-rust oil which against rust during the shipment.

Then the workers began to sleeve SS 304 Threadolets BSP into plastic bag individually, and put them in cartons & wooden cases, finally bundled wooden cases with nylon rope.

Threadolet BSP Package

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. great care is taken during operation and transportation.

Inspection Process of Stainless Steel Threadolet

- Visual the surface of threaded olet.

- Check the marking ‘ 1″ 3000# SS 304 BSPT MSS-SP-97 Z168″

- Measure dimensions. Such as run outlet dimension, branch outlet dimension, wall thickness.

- Test the chemical properties of stainless steel threadolet.

304 Stainless Steel Forging

304 Stainless Steel Properties

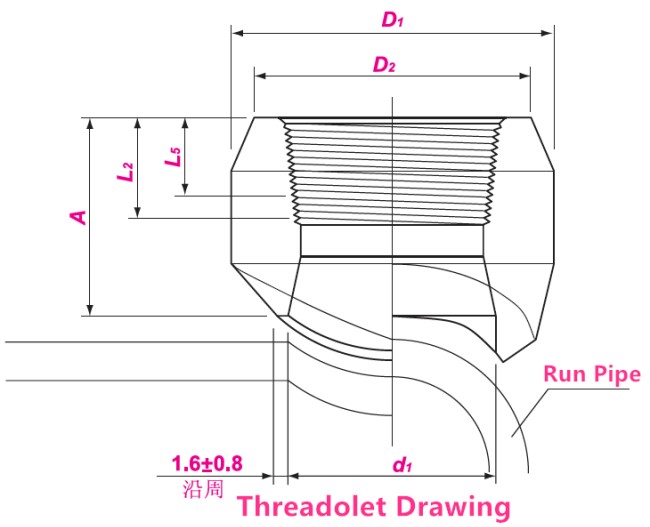

Drawing & Specification for Threadolet

Thread shall be machined per ASME B1.20.1

Threadolet Drawing & Specification

| Nominal Size | Branch Nominal Size | Length | OD of Fitting | OD at End Branch | Thread Length | Cut Hole Dia. | ||||||

| DN | NPS | DN | NPS | A | D 1 min | D 2 min | L2 min | d 1 nom | ||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | |||||

| 8~900 | 1/4~36 | 6 | 1/8 | 19 | – | 27 | – | 22 | – | 6.7 | 16 | – |

| 10~900 | 3/8~36 | 8 | 1/4 | 19 | – | 27 | – | 22 | – | 10.2 | 16 | – |

| 15~900 | 1/2~36 | 10 | 3/8 | 21 | – | 30 | – | 25 | – | 10.4 | 19 | – |

| 20~900 | 3/4~36 | 15 | 1/2 | 25 | 32 | 38 | 45 | 33 | 42 | 13.6 | 24 | 19 |

| 25~900 | 1~36 | 20 | 3/4 | 27 | 37 | 47 | 52 | 39 | 48 | 13.9 | 30 | 25 |

| 32~900 | 1 1/4~36 | 25 | 1 | 33 | 40 | 56 | 63 | 48 | 58 | 17.3 | 36 | 33 |

| 40~900 | 1 1/2~36 | 32 | 1 1/4 | 33 | 41 | 66 | 72 | 58 | 67 | 18 | 45 | 38 |

| 50~900 | 2~36 | 40 | 1 1/2 | 35 | 43 | 75 | 83 | 64 | 77 | 18.4 | 51 | 49 |

| 65~900 | 2 1/2~36 | 50 | 2 | 38 | 52 | 90 | 104 | 77 | 93 | 19.2 | 65 | 59 |

| 80~900 | 3~36 | 65 | 2 1/2 | 46 | – | 105 | – | 94 | – | 28.9 | 76 | – |

| 100~900 | 4~36 | 80 | 3 | 51 | – | 124 | – | 114 | – | 30.5 | 94 | – |

| 125~900 | 5~36 | 100 | 4 | 57 | – | 154 | – | 140 | – | 33 | 121 | – |

45 Degree Long Radius Elbow

6” STD 45 Degree Long Radius Elbow Seamless ASTM A420 WPL6 ASME B16.9

USD8 USD7

Stainless Steel Eccentric Reducer

4"×3" Sch40S Stainless Steel Eccentric Reducer ASTM A403 WP304 ASME B16.9

USD15 USD13