- Home

- Blog Custom Layout

- Steel Pipe Caps

- Galvanized Pipe Cap

Galvanized Pipe Cap

USD7 USD6.5

Galvanized Seamless Pipe Cap 6" Sch40 ASTM A234 WPB

- General Details

- Technical Info

- BW Specification

- SW Specification

- Documents

- Related Products

Galvanized pipe cap fittings are used in most applications with the exception of underground lines, they have the ability to protect against corrosion and salt. But they should not be used with gas application.

We take steel pipe cap to act as protective device to close off end of pipe and stop the flow of fluids.

What is Galvanized Steel Pipe?

Galvanized pipes have been coated with a layer of zinc. The zinc provides a barrier against corrosion so that the pipe may be exposed to the outdoor environmental elements. The protective barrier proves equally effective against damage from indoor humidity.

Types of Galvanized Pipe Caps

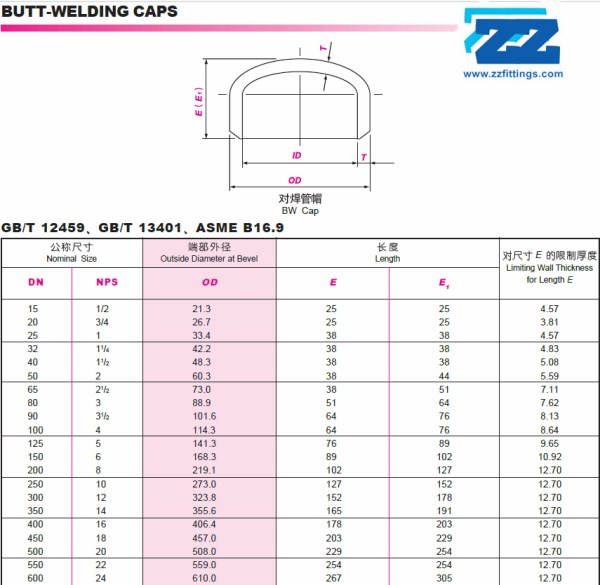

Butt Weld Cap

Usually we surface the pipe cap in hot dip galvanized. It produces a zinc coating by completely immersing the steel product in a bath of molten zinc. Prior to immersion in the zinc bath, the steel is chemically cleaned to remove all oils, greases, soil, mill scale, and oxides.

Supply Range

Size: 1/2″ to 48″

Thickness: Sch 10S, 20, STD, 40, XS, 80, 160, XXS

Material: Carbon Steel, Alloy Steel, Stainless Steel.

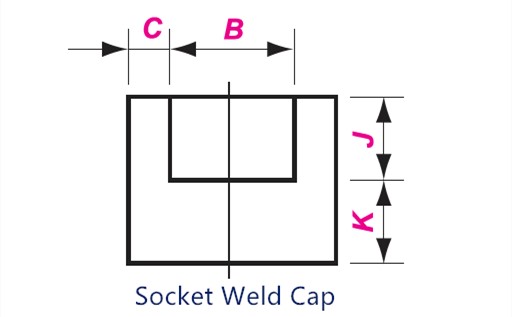

Socket Weld Cap & Threaded Cap

There are two methods for forged steel fittings, hot dip and cold galvanizing. Usually customer prefer the cold galvanized pipe cap, because it is cheap and pretty. We manufacture the socket weld fittings & threaded fittings in small size, generally below 4 inch.

Supply Range

Size: 1/8″ to 4″

Pressure: 3000lb, 6000lb, 9000lb

Material: Carbon Steel, Alloy Steel, Stainless Steel.

Galvanized Pipe Fittings vs Black Pipe Fittings

From the name, we can know galvanized pipe fittings have a zinc coating while black pipe fitting usually painting.

For transportation, galvanized steel pipe is suitable for transferring the water, if oil & gas, that may lead a burst. So we take the black steel pipe to carry the oil and gas for project.

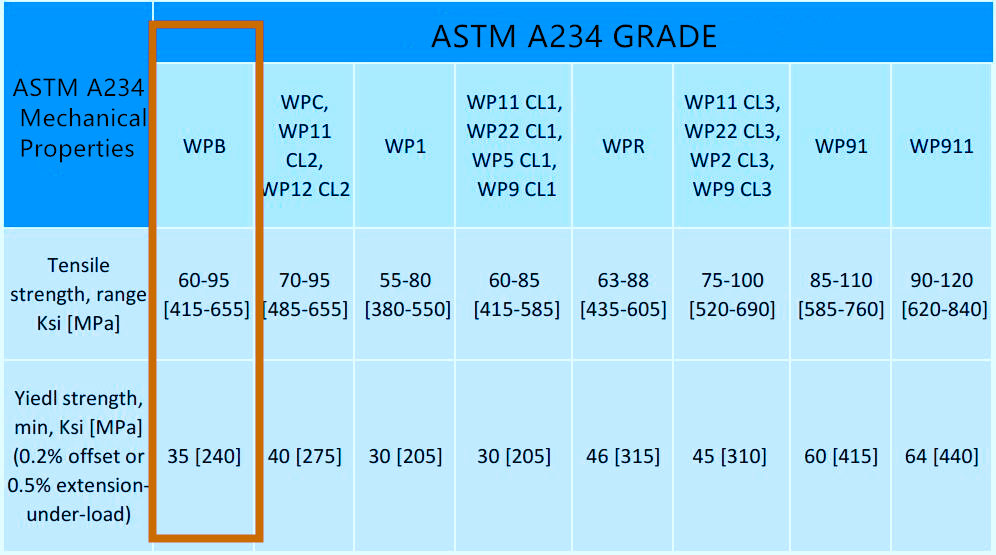

ASTM A234 Properties

ASTM A234 Buttweld Fittings Mechanical Properties

Butt Weld Cap Specification

Drawing & Specification for Socket Weld Cap

Socket Weld Cap Drawing

| Nominal Size | Socket Bore Dia. | Socket Wall Thickness | Depth of Socket | End Wall Thickness | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | B | C | Jmin | Kmin | |||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | |||||||

| ave | min | ave | min | ave | min | |||||||

| 6 | 1/8 | 10.9 | 3.18 | 3.18 | 3.96 | 3.43 | / | / | 9.5 | 4.8 | 6.4 | / |

| 8 | 1/4 | 14.3 | 3.78 | 3.30 | 4.60 | 4.01 | / | / | 9.5 | 4.8 | 6.4 | / |

| 10 | 3/8 | 17.7 | 4.01 | 3.50 | 5.03 | 4.37 | / | / | 9.5 | 4.8 | 6.4 | / |

| 15 | 1/2 | 21.9 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 9.5 | 6.4 | 7.9 | 11.2 |

| 20 | 3/4 | 27.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 12.5 | 6.4 | 7.9 | 12.7 |

| 25 | 1 | 34.0 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 12.5 | 9.6 | 11.2 | 14.2 |

| 32 | 1 1/4 | 42.8 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 12.5 | 9.6 | 11.2 | 14.2 |

| 40 | 1 1/2 | 48.9 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 12.5 | 11.2 | 12.7 | 15.7 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 16.0 | 12.7 | 15.7 | 19.0 |

| 65 | 2 1/2 | 73.9 | 8.76 | 7.62 | / | / | / | / | 16.0 | 15.7 | 19.0 | / |

| 80 | 3 | 89.9 | 9.52 | 8.30 | / | / | / | / | 16.0 | 19.0 | 22.4 | / |

| 100 | 4 | 115.5 | 10.69 | 9.35 | / | / | / | / | 19.0 | 22.4 | 28.4 | / |

Socket Weld Reducing Tee

1 x 1 x 1/2 Socket Weld Reducing Tee Class 6000 ASTM A182 F316 ASME B16.11

USD21 USD20