- Home

- Blog Custom Layout

- Steel Pipe Tees

- Socket Weld Tee

Socket Weld Tee

USD20 USD18

Equal Tee SW 1" 3000lbs A182 F304L ASME B16.11

- General Details

- Technical Info

- Specification

- Documents

- Related Products

Socket weld fittings are available in tee, elbow, coupling, cap, union, cross. They are used to the systems requiring exceptional strength of welded joints.

Steel pipe tee can be divided into straight or equal tee and reducing tee. Depending on the run pipe and branch diameter.

We are known as specialist in ASME B16.11 / BS3799 socket weld fittings, and supply different size, grades, specification, thickness as customer’s requirements.

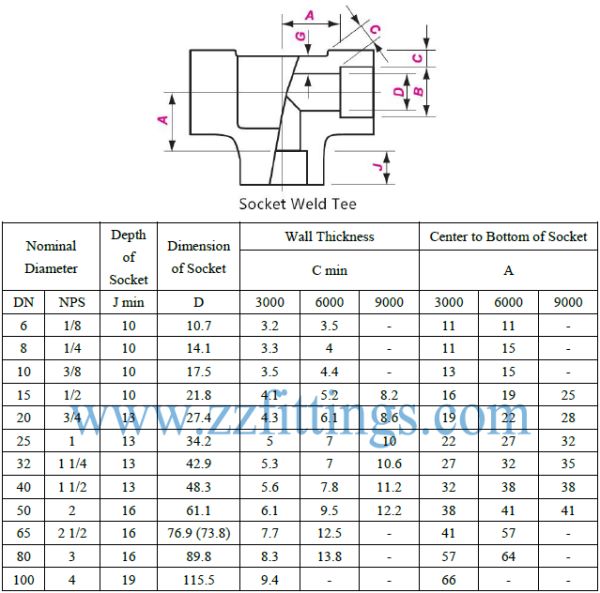

Socket Weld Tee Dimensions and Type

| Size | 1/8”, 1/4”, 3/8”, 1/2”, 3/4”, 1”, 1 1/4”, 1 1/2”, 2”, 2 1/2”, 3”, 4” |

|---|---|

| Pressure | 3000LB, 6000LB, 9000LB |

| Standard | ASME, JIS, DIN, GB/T, BS |

Socket Weld Tee Dimensions

- The even thickness around the socket bore shall not be less than the average value, the thickness at partial areas can be the min one.

- Considering the tolerance of outside diameter of pipe, the diameters of some socket bore can be a little larger than the ones specified in B16.11

- When the sizes of the connecting pipes are not conformed to the ones specified in this catalog, the sizes of the connecting pipes shall be provided in the purchase specification.

Socket Weld Equal Tee

The branch diameter is same as run pipe diameter. So we also call it as straight tee. They are widely used in the small piping system.

Socket Weld Reducing Tee

As the other reducing pipe fittings, reducing tee has the different diameter for the ends. So they can change fluid direction, speed and volume.

What is Socket Weld?

ASME Socket Weld Tee Weight Chart

The weight chart of socket weld tee is based on the ASME B16.11 and BS3799 standard specification, which covers Class 3000lb, 6000lb and 9000lb.

| Nominal Size | Approximate Weight/kg | |||

| DN | NPS | 3000 LB | 6000 LB | 9000 LB |

| 6 | 1/8 | 0.13 | 0.22 | |

| 8 | 1/4 | 0.13 | 0.22 | |

| 10 | 3/8 | 0.16 | 0.45 | |

| 15 | 1/2 | 0.35 | 0.55 | 1.15 |

| 20 | 3/4 | 0.4 | 0.9 | 1.8 |

| 25 | 1 | 0.66 | 1.46 | 2.25 |

| 32 | 1 1/4 | 1 | 1.9 | 3.95 |

| 40 | 1 1/2 | 1.4 | 3.4 | 4.87 |

| 50 | 2 | 2.2 | 3.7 | 8.89 |

| 65 | 2 1/2 | 4 | 7.2 | |

| 80 | 3 | 6.15 | 10.7 | |

| 100 | 4 | 14.3 | ||

Stainless Steel Socket Weld Fittings

ASTM A182 F304, F304L, F304H, F316, F316L, F309, F310, F317, F321, F947

The material are conform to ASME A182 and dimensions for stainless steel forged fittings conform to ASME B16.11

Carbon Steel Socket Weld Fittings

ASTM A105, A350 LF2 & LF3, A694 F52, F56, F60, F65, F70

The material are conform to ASTM/ASME A105/SA105 and dimensions for carbon steel forged fittings conform to ASME B16.11

Certificates for Customer

Commercial invoice and packing list for custom clearance.

Certificate of origin help customer to reduce the import tax.

EN10204 3.1 mill test certificate guarantee the quality.

Bill of loading (BL) used to pick up the goods.

ASTM A182 F304 Chemical Properties

| Grade | C | Mn | P | S | Si | Ni | Cr |

| F 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 8 ~ 11 | 18 ~ 20 |

| F 304 H | 0.04 | 2 | 0.045 | 0.03 | 1 | 8 ~ 11 | 18 ~ 20 |

| F 304 L | 0.03 | 2 | 0.045 | 0.03 | 1 | 8 ~ 13 | 18 ~ 20 |

| F 304N | 0.08 | 2 | 0.045 | 0.03 | 1 | 8 ~ 10.5 | 18 ~ 20 |

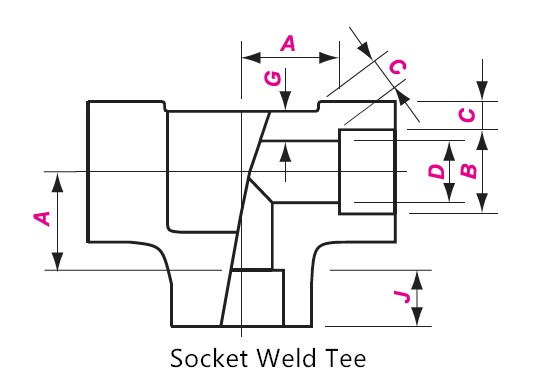

Drawing & Specification for Socket Weld Tee

Drawing of Socket Weld Tee

| Nominal Size | Socket Bore Dia. | Bore Dia. of Fittings | Socket Wall Thickness | Body Wall | Depth of Socket | Center to Bottom of Socket | ||||||||||||

| D | C | Gmin | Jmin | A | ||||||||||||||

| DN | NPS | B | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 |

|

6000 | 9000 | ||||

| ave | min | ave | min | ave | min | |||||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | – | 3.18 | 3.18 | 3.96 | 3.43 | – | – | 2.41 | 3.15 | – | 9.5 | 11 | 11 | – |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | – | 3.78 | 3.3 | 4.6 | 4.01 | – | – | 3.02 | 3.68 | – | 9.5 | 11 | 13.5 | – |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | – | 4.01 | 3.5 | 5.03 | 4.37 | – | – | 3.2 | 4.01 | – | 9.5 | 13.5 | 15.5 | – |

| 15 | 1/2 | 21.9 | 15 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19 | 25.5 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19 | 22.5 | 28.5 |

| 25 | 1 | 34 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27 | 32 |

| 32 | 1 1/4 | 42.8 | 34.3 | 28.7 | 22 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 | 27 | 32 | 35 |

| 40 | 1 1/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32 | 38 | 38 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 | 38 | 41 | 54 |

| 65 | 2 1/2 | 73.9 | 61.2 | – | – | 8.76 | 7.62 | – | – | – | – | 7.01 | – | – | 16 | 41 | – | – |

| 80 | 3 | 89.9 | 76.4 | – | – | 9.52 | 8.3 | – | – | – | – | 7.62 | – | – | 16 | 57 | – | – |

| 100 | 4 | 115.5 | 100.7 | – | – | 10.69 | 9.35 | – | – | – | – | 8.56 | – | – | 19 | 66.5 | – | – |

Class 3000 Socket Weld Fittings

Socket Weld Fittings 1" Class 3000 Elbow ASTM A182 F316 ASME B16.11

USD16 USD15

Threaded Half Coupling

2” Class 6000 Threaded Half Coupling BSPP ASTM A182 F22 ASME B16.11

USD56 USD55

8 Inch Pipe Cap A403 WP304

8 Inch Steel Pipe Cap Sch40S Seamless BW ASTM A403 WP304 ASME B16.9

USD37 USD36

ASTM A105 Reducing Tee Galvanized

Reducing Tee SW DN40 X DN32 Class 3000 Galvanized ASTM A105 ASME B16.11

USD19 USD18