- Home

- Blog Custom Layout

- Steel Pipe Tees

- Carbon Steel Tee

Carbon Steel Tee

USD95 USD92

Equal Tee 8" STD ASTM A420 WPL6 ASME B16.9

- General Details

- Technical Info

- BW Specification

- THD Specification

- Documents

- Related Products

Our Carbon Steel Tee is highly appreciated by customers for its superior quality and optimum finish. It is available in socket weld, butt weld and screwed. We can also fabricated other form according to the demands of the customers.

A pipe tee is also called triplet,three way and “T” pieces and it can be used to either combine or split a fluid flow. There are two types that equal tee and reducing tee.

Equal Tee vs Reducing Tee

Reducing Tee vs Equal Tee

Equal tee has same inlet and outlet sizes, but reducing tees has the one or two ends different in dimension. Due to this, that makes the tee fittings with the capacity to control the volume when required.

Equal Tee Weight Chart

The weight unit is kg/pcs. It covers all types of equal tee, such as socket weld, threaded and butt weld.

| Nominal Size | Socket Weld Equal Tee | Threaded Equal Tee | Butt Weld Equal Tee | |||||||

| DN | NPS | 3000 LB | 6000 LB | 9000 LB | 2000 LB | 3000 LB | 6000 LB | SCH40 | SCH80 | SCH160 |

| 6 | 1/8 | 0.13 | 0.22 | 0.13 | 0.22 | 0.35 | ||||

| 8 | 1/4 | 0.13 | 0.22 | 0.13 | 0.22 | 0.57 | ||||

| 10 | 3/8 | 0.16 | 0.45 | 0.16 | 0.4 | 0.66 | ||||

| 15 | 1/2 | 0.35 | 0.55 | 1.15 | 0.35 | 0.58 | 1.15 | 0.2 | 0.2 | |

| 20 | 3/4 | 0.4 | 0.9 | 1.8 | 0.45 | 0.9 | 1.8 | 0.2 | 0.3 | |

| 25 | 1 | 0.66 | 1.46 | 2.25 | 0.66 | 1.46 | 2.25 | 0.3 | 0.5 | |

| 32 | 1 1/4 | 1 | 1.9 | 3.95 | 1 | 1.9 | 3.95 | 0.6 | 0.7 | |

| 40 | 1 1/2 | 1.4 | 3.4 | 4.87 | 1.4 | 3.4 | 4.87 | 0.9 | 1.3 | 1.5 |

| 50 | 2 | 2.2 | 3.7 | 8.89 | 2.2 | 3.8 | 8.89 | 1.5 | 2.2 | 2.7 |

| 65 | 2 1/2 | 4 | 7.2 | 4.2 | 7.2 | 12.8 | 2.7 | 3 | 3.1 | |

| 80 | 3 | 6.15 | 10.7 | 6.15 | 10.7 | 21.8 | 3.8 | 4.3 | 5.5 | |

| 100 | 4 | 14.3 | 14.7 | 17.9 | 29.5 | 4.6 | 6 | |||

How Many Types of Carbon Steel Pipe Tee?

Socket Weld Tee

Socket weld tees have a recess for the pipe to slip into, after which a back weld is applied to hold the pipe in the fittings. These fittings are formed by either upset forging or drop forging method.

Supply Range

Size: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/2″, 2″, 2 1/2″, 3″, 4″.

Standard: ASME B16.11 & BS3799

Pressure Rating: Class 3000, 6000, 9000

Surface: Anti-rust Oil

Coating: Galvanized Socket Weld Tee

Carbon Steel Threaded Tee

Threaded tees are used in low and high pressure systems. These fittings allow quick construction and frequent disassembly and assembly for repairs.

Supply Range

Size: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/2″, 2″, 2 1/2″, 3″, 4″.

Standard: ASME B16.11 & BS3799

Pressure Rating: 2000lb, 3000lb, 6000lb

Thread Type: NPT, BSPP, BSPT

Surface: Anti-rust Oil and Galvanized.

Carbon Steel Butt Weld Tee

We made butt weld tees by wrought materials in both seamless and welded construction. Welding the tee fittings to the pipe causes it to be leak-proof, adds strength, utilizes a small amount of space and minimizes the possibility of erosion and corrosion

Supply Range

Standard: ASME B16.9, SH3408, HG/T21635, HG/T21631, SY/T0510

Size: 1/2″, 1″, 2″, 3″, 4″, 6″, 8″, 10″, 12″, 16″, 20″, 24″ to 60″

Schedule: Sch 20, STD, Sch 40, XS, Sch 80, Sch 100, Sch 120, Sch 140, Sch 160, XXS

End: Plain ( PE) or Bevel (BE)

Surface: Blasting and Painting, PE Coating, Hot Dip Galvanized.

Carbon Steel Grades

A860 WPHY42 Reducing Tee

ASTM A860 WPHY 52 Equal Tee

ASTM A860 WPHY 60 Reducing Tee

Forged Steel Fittings

ASTM A105 Socket Weld Tee

A350 LF2 & LF3 Forged Steel Tee

A694 F52 & F60 Threaded Pipe Tee

694 F65 & F70 Class 3000LB Screw Tee

Charpy Impact for ASTM A420 WPL6

| Size of Specimen | A | B |

| mm | J | J |

| 10 by 10.0 | 17.6 | 13.6 |

| 10 by 7.5 | 13.6 | 10.8 |

| 10 by 5.0 | 9.5 | 7 |

| 10 by 2.5 | 5.4 | 4.1 |

A – Charpy V-Notch Impact Value Required for Acceptance (Average of Three Specimens).

B – Minimum Charpy V-Notch Impact Value Without Requiring Retest (One Specimen Only of a Set).

The impact test temperature shall be -50°F[-45°C] for ASTM A420 WPL6.

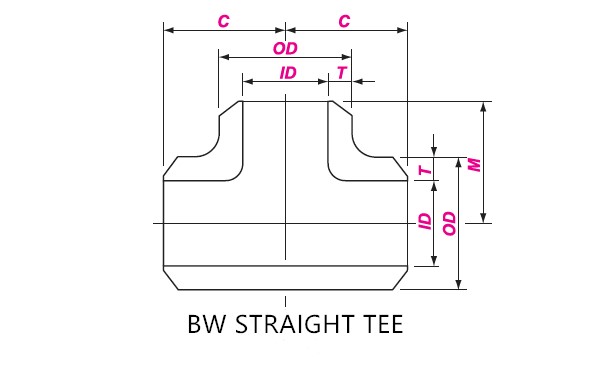

BW EQUAL TEE DRAWING

| Nominal Size | Outside Diameter at Bevel | Center to End | ||

| DN | NPS | OD | C | M |

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 29 | 29 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 1 1/4 | 42.2 | 48 | 48 |

| 40 | 1 1/2 | 48.3 | 57 | 57 |

| 50 | 2 | 60.3 | 64 | 64 |

| 65 | 2 1/2 | 73 | 76 | 76 |

| 80 | 3 | 88.9 | 86 | 86 |

| 125 | 5 | 141.3 | 124 | 124 |

| 150 | 6 | 168.3 | 143 | 143 |

| 200 | 8 | 219.1 | 178 | 178 |

| 250 | 10 | 273 | 216 | 216 |

| 300 | 12 | 323.8 | 254 | 254 |

| 350 | 14 | 355.6 | 279 | 279 |

| 400 | 16 | 406.4 | 305 | 305 |

| 450 | 18 | 457 | 343 | 343 |

| 500 | 20 | 508 | 381 | 381 |

| 550 | 22 | 559 | 419 | 419 |

| 600 | 24 | 610 | 432 | 432 |

| 650 | 26 | 660 | 495 | 495 |

| 700 | 28 | 711 | 521 | 521 |

| 750 | 30 | 762 | 559 | 559 |

| 800 | 32 | 813 | 597 | 597 |

| 850 | 34 | 864 | 635 | 635 |

| 900 | 36 | 914 | 673 | 673 |

| 950 | 38 | 965 | 711 | 711 |

| 1000 | 40 | 1016 | 749 | 749 |

| 1050 | 42 | 1067 | 762 | 711 |

| 1100 | 44 | 1118 | 813 | 762 |

| 1150 | 46 | 1168 | 851 | 800 |

| 1200 | 48 | 1219 | 889 | 838 |

| 1300 | 52 | 1321 | 965 | 914 |

| 1400 | 56 | 1422 | 1041 | 965 |

| 1500 | 60 | 1524 | 1118 | 1016 |

| 1600 | 64 | 1626 | 1194 | 1092 |

| 1700 | 68 | 1727 | 1270 | 1168 |

| 1800 | 72 | 1829 | 1320 | 1245 |

| 1900 | 76 | 1930 | 1422 | 1320 |

| 2000 | 80 | 2032 | 1499 | 1397 |

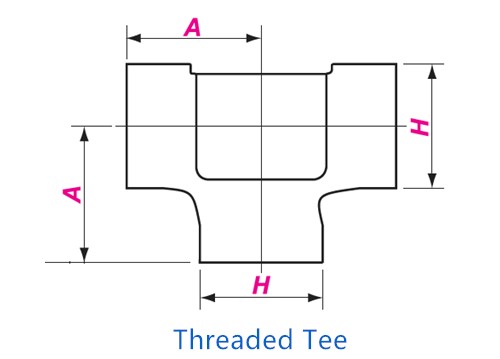

Drawing & Specification for Threaded Equal Tee

Threaded Tee Drawing

| Nominal Size | Center-to-End | Outside Diameter of Band | |||||

| DN | NPS | A | H | ||||

| 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | ||

| 6 8 10 |

1/8 1/4 3/8 |

21 21 25 |

21 25 28 |

25 28 33 |

22 22 25 |

22 25 33 |

25 33 38 |

| 15 20 25 |

1/2 3/4 1 |

28 33 38 |

33 38 44 |

38 44 51 |

33 38 46 |

38 46 56 |

46 56 62 |

| 32 40 50 |

1 1/4 1 1/2 2 |

44 51 60 |

51 60 64 |

60 64 83 |

56 62 75 |

62 75 84 |

75 84 102 |

| 65 80 100 |

2 1/2 3 4 |

76 86 106 |

83 95 114 |

95 106 114 |

92 109 146 |

102 121 152 |

121 146 152 |

Stainless Steel Elbow

Elbow 90 Degree LR DN200 Sch 10S PE Coated A403 WP316 ASME B36.19

USD115 USD111